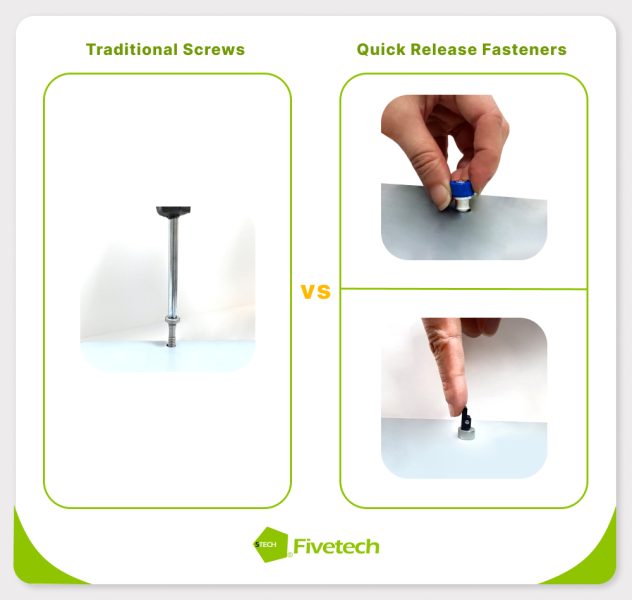

Quick release fasteners offer the convenience of securing components with just a quarter turn, or 90-degree, twist, requiring no tools for installation or removal. This stands in contrast to traditional screws and bolts, which revolutionizes assembly processes across various sectors.

Regarding applications, quick-release screws are ideal when frequent access is required. This could be for regular maintenance, adjustments, or equipment upgrades. They are especially useful in industries such as electronics and automation, where components need to be accessed regularly for servicing or replacement.

Interested in checking out our range of classified products?

Click Here to make your design alive!

Types of Quick Release Fasteners in Fivetech

Click each type name to see more details!

| Fivetech Quick Release Fasteners

(Click the links below to browse the product category) |

Features | Applications | |

| Captive Fastener |

|

Used in compact electronic devices, telecom equipment, servers, and any application requiring secure, removable access panels. | |

| Captive Lock |

|

|

|

| M.2 Screws / M.2 Board Latches |

|

Perfect for securing M.2 SSDs in various electronics, such as laptops, desktops, servers, and industrial PCs. | |

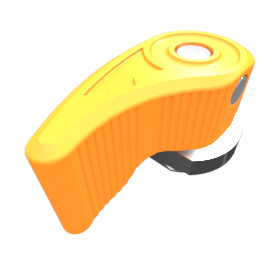

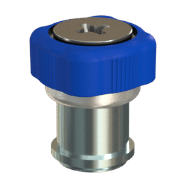

| Quarter Turn Fastener |

|

Used in aerospace, automotive, electronics, and other industries that require secure, removable panels and components. | |

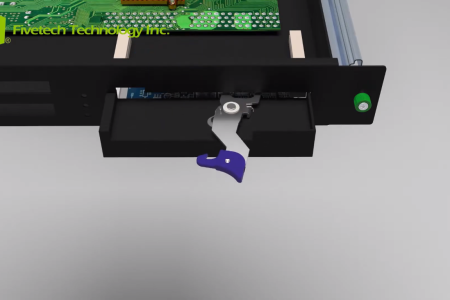

| Ejector |

|

|

|

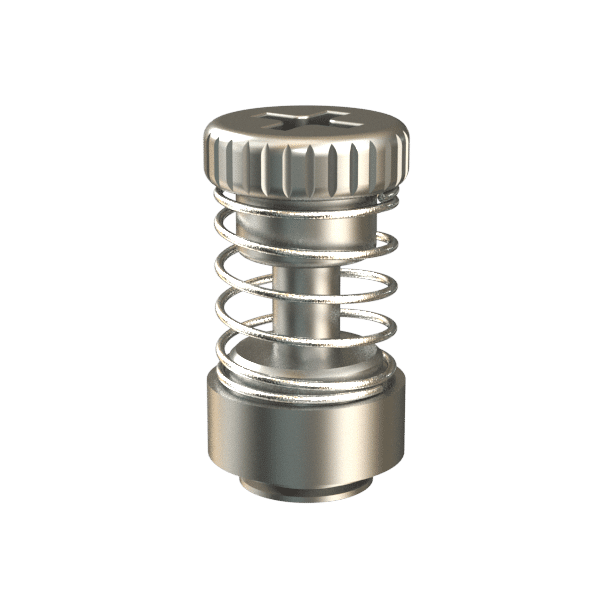

Captive Fastener

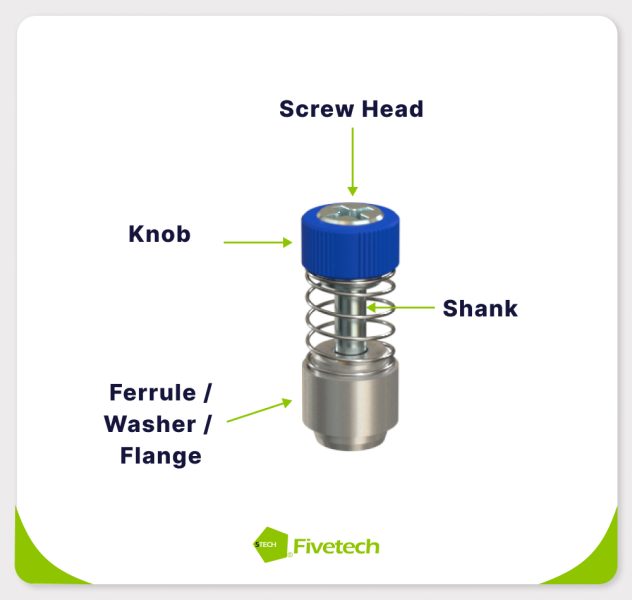

Captive fasteners/screws, unlike traditional screws, will remain attached to the equipment when loosened. They feature a partially-threaded screw head, as well as its reduced shank diameter and permanently attached washer (flange) that form a captive retention mechanism, allowing the narrow shank to pass through a clearance hole in the tethered component to be screwed into by rotating, while the wide washer prevents the quick-release screw from detaching completely.

This eliminates the risk of losing screws during maintenance or disassembly, and also allows the screws to be easily installed/removed with your hands or machine press, reducing downtime and simplifying future procedures, thus making them vital in industries like machinery, electronics, furniture, and automotive.

Fivetech offers a wide variety of captive fastener designs, including captive screw, angle screw, infinity thumb screw, security screw, and more, to cater to a diverse range of needs. Material selection ranges from stainless steel, aluminum, and plastic, all suitable for varying applications.

- Stainless steel: though heavier, provides the highest strength and durability, ideal for high-stress applications, environments with extreme temperatures or corrosion risks.

- Aluminum: offers a good balance between strength and weight, but its corrosion-resistance may depend on the specific alloy, so it’s more suitable for general-purpose applications where weight reduction is desired.

- Plastic: may have less strength and durability, but it is a lightweight and cost-effective option with good insulation properties, thus ideal for low-stress applications where weight is a major concern.

Click Captive Fastener – Fivetech to explore our latest quick-release screw products and solutions!

Delve into our article, Ultimate Guide to Captive Screws: Types & Applications, to explore further information!

| Picture | Product | Head diameter | Thread | Outer Panel Dimensions | Screw Projection | Knob Height | ||||

| A Min | A Max | T | P-1 | P-2 | H1 | H2 | ||||

|

13 Series Captive Screw | Ø8.5mm | M3*0.5 | 0.8 | ~ | 13.8 | 3.45 | 6.1 | 10.35 | 7.70 |

|

32 Series Captive screw | ∅11.5mm | 6-32 | 0.8 | ~ | – | 0.4 | 5.1 | 16.1 | 11.4 |

|

34 Series Captive screw | Ø18mm | M3/#6-32 | 0.8 | ~ | – | 1.3/3.3 | 5.8/7.8 | 16.7 | 12.2 |

|

41 Series Fastener Screw (Mini knob) | Ø6.5mm | M3*0.5 | 1.0 | ~ | 11.6 | 0.6 | 3.8 | 11 | 7.8 |

|

43 Series Captive screw | Ø11.5mm | #6-32 | 0.8 | ~ | 10.8

|

0.6 | 4.3 | 10.2 | 6.5 |

| Ø11.5mm | #6-32 | 0.8 | ~ | 12.8 | 1.4 | 5.1 | 10.2 | 6.5 | ||

|

44 Series Fastener Screw (Hex) | ∅6.5mm | M3 | 0.8 | ~ | 16.5 | 2.5 | 6.9 | 14.0 | 9.6 |

|

Fastener Screw – | Ø7mm | M3*0.5 | 0.8 | ~ | 15.4 | 0.6 | 4.7 | 14.8 | 10.7 |

|

Captive Screw- | ∅11mm | M3*0.5 | 1.0 | ~ | 15.6 | 0.3 | 4.6 | 15.3 | 11.0 |

|

Captive Screw- | ∅11mm | M3*0.5 | 0.8 | ~ | 12.6 | ~ | 3.6 | 12.7 | 9.0 |

|

27 Series – Smooth Knob-Press in | Ø10mm | M3 | 0.8 | ~ | 15.6 | 0.5 | 4.4 | 15.1 | 11.2 |

| 27 Series – Smooth Knob-Flare in | Ø10mm | M3 | 1.0 | ~ | 15.6 | 0.6 | 4.2 | 15.2 | 11.4 | |

|

27 Series Captive Screw-Floating | Ø13mm | M5 | 0.8 | ~ | 21.2 | 5.0 | 10 | 16.2 | 11.2 |

|

27 Series – High Profile | Ø13.35mm | M5*0.8 | 1.6 | 2.5 | 31.5 | 1.7 | 13.5 | 29.8 | 18 |

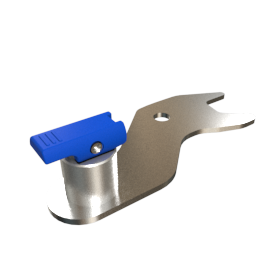

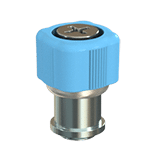

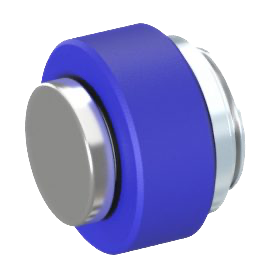

Captive Lock / Bolt

While captive screws prevent screw loss during maintenance and operation, captive locks allow for quicker installation and removal, and also prevent accidental disengagement in critical applications.

Unlike the basic quick-release screw, captive locks incorporate a locking feature that typically involves a spring-loaded latch or detent mechanism, which will engage with a designated slot or receiving feature. The spring will then provide tension to the latch/detent, ensuring a firm lock with the receiving feature, which will be secure even under vibration or impact.

Fivetech provides diverse types of captive locks, including angle, positioning, and non positioning locks. We also utilize high-quality materials such as 300 series stainless steel that provide excellent corrosion resistance and durability, as well as carbon steel or aluminum that offers a balance of strength and affordability. The metal combination for the pin, spring, rivet, and ferrule will depend on the specific design of the quick-release screw, while our wrench and knob are made with plastic to ensure better grip, insulation, and weight reduction.

Click Captive Lock – Fivetech to explore our latest products and solutions!

|

|

(Reference Only) |

|

Angle Lock

|

Positioning Lock

|

Non Positioning Lock

|

| Series No and Introduction | Series No and Introduction | Series No and Introduction |

M.2 Screws / M.2 Board Latches

The M.2 board latch is an efficient solution for securing M.2 SSDs, offering a time-saving and tool-free alternative to traditional screws, as it utilizes a one-touch mechanism for effortless attachment and removal. All you have to do is pull back the M.2 board latch’s buckle, press down the M.2 card, then release the buckle to secure it in place. This can prevent over-tightening or incompatibility issues that were common with the use of traditional screws, and it also reduces the risk of damaging the delicate SSD components.

Fivetech currently offers three main types, including the Basic M.2 Board Latch, Double M.2 Board Latch, and Buckle Lock Double M.2 Board Latch. All options have various mounting methods, such as the snap-in turn type, SMT type, screw-in type, and snap-in type.

Click M.2 Board Latch – Fivetech to explore our latest products and solutions!

Delve into our article, An M.2 Screw Alternative: A Deep Dive into M.2 Board Latches, to explore further information!

|

|

|

|

Buckle Lock Double M.2 Board Latch

|

Double M.2 Board Latch

|

M.2 Board Latch

|

| NA | Series No and Introduction | Series No and Introduction |

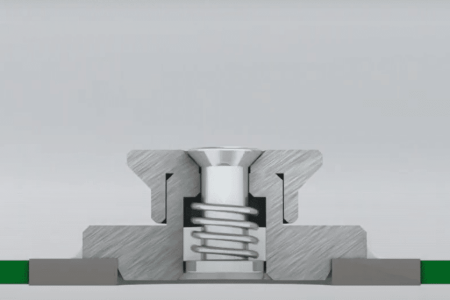

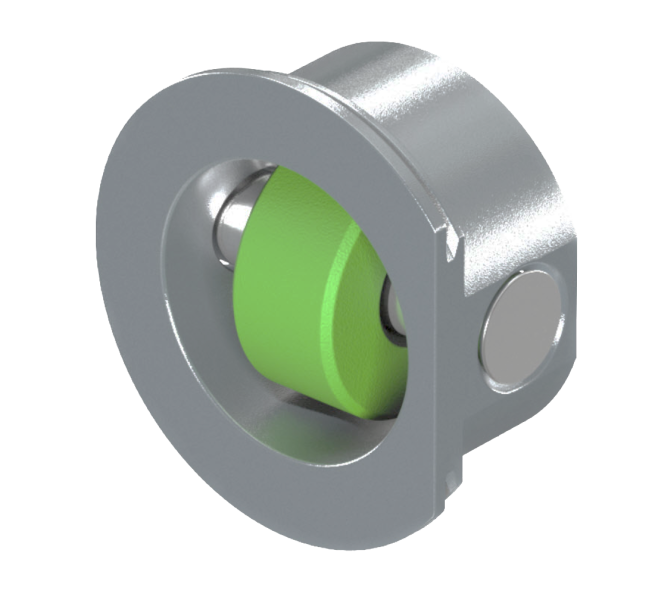

Quarter Turn Fastener

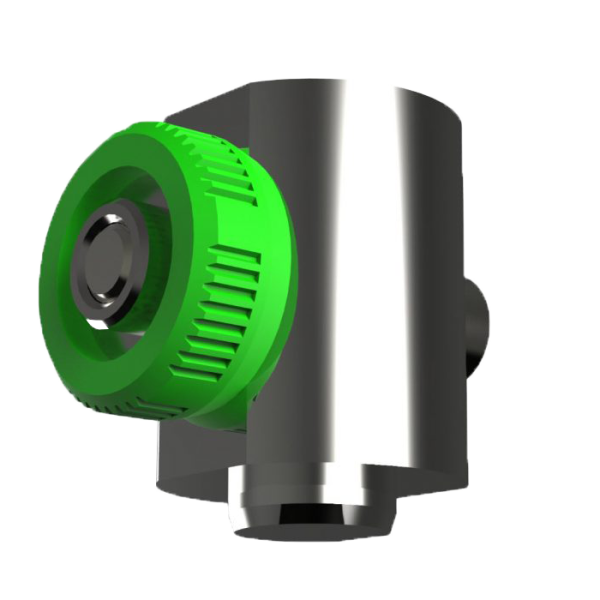

Quarter turn fastener features “push-turn-lock, turn-unlock” action, reducing the time taken for installation and removal. You may operate it manually or with a tool, depending on the type of stud head, by turning the stud 90° to activate the cam, which will drive the cross pin against the receptacle, creating a secure locking engagement.

The connection is maintained by the tension created by the spring within the stud or receptacle, whereas the joint (ferrule) provides increased stability and load distribution around the panel or component that’s being secured, even under vibration or stress. To unlock the fastener, simply rotate the stud in the opposite direction for easy, tool-free removal.

Moreover, with winged heads or arrow-marked knobs, quarter turn fasteners provide a clear visual indication of its locked/unlocked state, offering more operational convenience. They are also very versatile, ideal for attaching panels and covers of various materials for aerospace, automotive, electronics, and furniture.

Fivetech construction materials prioritize durability and offer design customization for specific applications. The spring of our quarter turn fastener is made out of stainless steel to provide excellent corrosion resistance and strength, ensuring consistent spring tension over time. The cross pin, on the other hand, uses carbon steel as a cost-effective option, which also creates significant force for the locking mechanism.

We also offer mounting options for SMT and press-in installations. Our SMT quarter turn fasteners are suitable for applications within space-constrained devices and PCBs that require low profile design; whereas the press-fit design is more robust, suitable for applications that require a higher level of strength, as well as faster installation and easier replacement.

Click Quarter Turn Fastener – Fivetech to explore our latest products and solutions!

|

|

(Reference Only) |

(Reference Only) |

|

Auto lock

|

Always Lock

|

Turn Lock

|

Auto block

|

| Series No and Introduction | Series No and Introduction | Series No and Introduction | Series No and Introduction |

Other Efficient Solutions from Fivetech: Ejector, Handle, and Roller

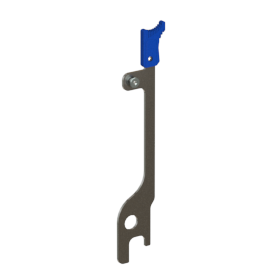

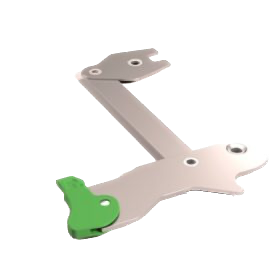

Ejector

Fivetech’s ejector is an all-in-one solution that combines pushing, pulling, and buckling functionalities, saving time while eliminating the need for multiple components. It features a user-friendly and ergonomically designed lever, which can act as a handle, allowing users to safely remove components with minimal force. Furthermore, the versatile and replaceable plastic head can latch onto chassises to help with positioning.

These features make ejectors particularly ideal for industries that handle sensitive electronics, such as cloud computing, servers, data centers, and electric vehicles. Thus, users can expect to effortlessly extract liquid coolers, electric vehicle batteries, or even disconnect the chassis from rear cables without the risk of damage. Even if you can’t find the right model, our R&D team can design customized ejectors based on your needs, ensuring a perfect fit to facilitate controlled and efficient hardware removal.

Click Ejector – Fivetech to explore our latest products and solutions!

|

(Reference Only) |

(Reference Only) |

(Reference Only) |

|

Rotate Ejector Handle

|

Auto Open Ejector

|

3 Bar Linkages Ejector

|

Spring Lock Ejector

|

| Series No and Introduction | Series No and Introduction | Series No and Introduction | Series No and Introduction |

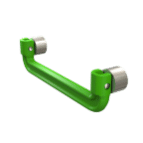

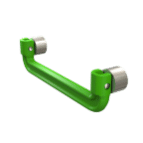

Handle

Fivetech innovative handle solutions, including the Pull Handle, Hinge Handle, Smart Angle Handle, Smart Folding Handle, and Retractive Handle, offer exceptional durability and ergonomics. These handles provide a secure grip while facilitating easy access to server racks, panels, and other devices. Fivetech smart folding handles stand out for space-saving design, stability, and 90-degree positioning, reducing noise and manual effort. For heavy-duty applications, retractable handles are recommended due to their ability to withstand high loads. Explore more in “A Guide to Folding Handles: Embracing Compactness and Functionality.

If you are interested in Fivetech folding handles, check out A Guide to Folding Handles: Embracing Compactness and Functionality.

| Picture | Product | Handle Diameter(ØD) | Pitch | Height | Thread |

|---|---|---|---|---|---|

|

6B 1U Series | – | 26 | 25 | M3/M4/6-32/8/32 |

|

6X 1U Series | – | 65.6 | 44.25 | M3 |

|

71 Series Retractive Handle | Ø6 | P1 57 P2 37 |

27 | M5 |

|

Low Profile Folding Handle | – | 50 | X | Min:0.8 |

|

Smart Folding Handle Module-Thread in | – | 39 | 35.75 | Min:1.0 |

|

Smart Folding Handle for GPU- Flare-in | – | 64 | X | Min:1.0 |

|

Smart Angle Handle | – | 80 | 111.7 | M14*2.0 |

|

60 Series | Ø6 | 30 | 20.2 | M3/M4/M5 6-32/8-32/10-32 |

| Ø6.35 | 64 | 26 | |||

| Ø8 | 30 | 31 | |||

| Ø8 | 50 | 28 | |||

| Ø10 | 150 | 40 | M5 | ||

|

66 Series | 6.4 | 28.5 | 27 | M3/M4 6-32/8-32 |

|

62 Series | Ø6.35 | 38.2 | 42.2 | M3/M4 6-32 8-32 |

| 64 | 34 | ||||

| 101 | 34 | ||||

| 149 | 39.3 | ||||

| 162 | 59 | ||||

|

Hinge Handle 5P Series | – | 30 | 40.2 | M3/M4 6-32 8-32 |

|

Plastic Hinge Handle- Floating | – | 64 | – | – |

|

Ring Pull Series-Ring Type | – | 32 | 35.5 | M6*1.0 |

|

Pull Handle (T Type) | – | 25 | 25 | M3*0.5 |

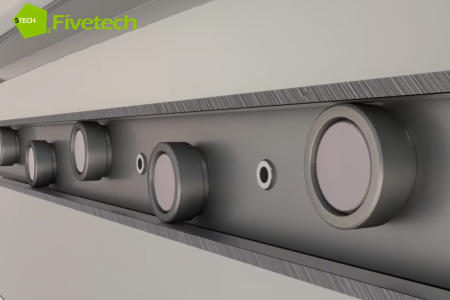

Roller

Rollers like the Slide Roller, Wheel Roller, Ball Roller, and Roller Bar are integral to Fivetech’s product line. They ensure smooth equipment movement, commonly used in pulling applications like vending machines or server cabinets. Widely applied in cloud technologies, AI, and 5G networks, rollers stand out for their low friction, minimal maintenance costs, but lack damping functionality for segmented pulling precision, requiring periodic checks for optimal performance.

Click Roller – Fivetech to explore our latest products and solutions!

(Reference Only) |

(Reference Only) |

(Reference Only) |

(Reference Only) |

|

Ball Roller

|

Wheel Roller

|

Roller Bar

|

Slide Roller

|

| Series No and Introduction | Series No and Introduction | Series No and Introduction | Series No and Introduction |

How to Select Quick Release Fastener

Choosing the right quick release fastener goes beyond cost-effectiveness. To ensure optimal performance for your specific applications, you also have to consider these 6 factors:

- Fastener Features: Some applications may require specific features. For instance, quick-release quarter-turn locks are better for components that require frequent assembly and disassembly. Other applications might even need special features like anti-loosening, vibration resistance, magnetic resistance, etc.

- Fastener Strength: Whether the fastener is for securing panels, enclosures, or other structures, you have to evaluate the weight of its expected load, including static and dynamic loads. This way, you can choose the type of fastener with the right shape and strength to withstand them.

- Dimensions and Tolerance: Consider the space limitations and the dimensions of the mating parts. Then, choose a fastener with the appropriate diameter, panel height, and thread size. You should also make sure that the tolerance meets the design requirements to ensure precise assembly. If you are unsure about the screw size, you can check out our guide on measuring screws here.

- Product Quality: Select fasteners that comply with international or industry standard specifications, such as ISO, ASTM, etc. These claims should also be backed up with relevant test reports, such as pull/push force, torque, and salt spray testing, to ensure consistent product quality.

- Environmental Conditions: Some applications may involve high temperatures, high humidity, corrosive environments, or SMT soldering with reflow ovens up to 260°C. In this case, select fasteners with durable materials, such as carbon steel, stainless steel, or certified heat-resistant and fire-retardant plastics. This will help to ensure the fastener’s long-term reliability. You may also request certifications from the manufacturer to verify that the fasteners can meet the performance requirements in specific environments.

- Installation Methods: Consider whether you have the required tools for installation and removal, such as riveting machines. You should also determine whether you need quick installation or removal, especially for critical servers that need to minimize downtime.

Reasons Quick-Release Fasteners Help Save Costs

Quick-release fasteners offer cost savings across various stages of an equipment’s lifecycle, from system design to daily operation, especially for servers and data centers. Here’s how:

- Minimizing Downtime: Every minute of downtime translates to lost revenue and productivity. Quick-release fasteners enable quick access to internal components for repairs, upgrades, or replacements. This reduces downtime and maintenance costs while minimizing financial losses from service interruptions.

- Optimizing Space Utilization: Quick-release fasteners like buckle lock double m.2 board latch facilitate denser component packing. This allows for more functionality within a smaller footprint, reducing the number of required servers and racks. In turn, users can lower hardware costs per unit of performance and reduce expenses related to data center space, cooling, and energy consumption.

- Simplifying Operations: The tool-free nature of these fasteners streamlines various operational procedures, including assembly, disassembly, and maintenance. Not only can they improve efficiency, but they can also reduce the risk of errors during handling, thus lowering labor costs and preventing expensive repairs.

- Enhancing System Flexibility: Quick-release fasteners support modular designs, allowing individual components to be easily swapped or upgraded. This reduces development time and costs for new systems as engineers can quickly adapt existing components for new applications. It also minimizes material waste due to the simplified prototyping and upgrading procedure, further optimizing costs.

How to Use Quick Release Fastener

Prepare Supplementary Components

Though not always necessary, using a flat washer with a quick-release fastener can enhance performance and durability. These basic washers come in various sizes and materials, such as steel, stainless steel, and nylon. They can distribute the load of a fastener over a larger surface area, reducing the risk of damage to the material.

For applications requiring more vibration resistance, you may consider incorporating NYLOK when installing quick-release fasteners. NYLOK is a specialized nylon adhesive patch that can fill the gaps between mating threads to create a powerful locking action upon engagement. It adds a layer of security to prevent loosening caused by vibration, shock, or repeated use.

Fastening Guide

While the specific installation process may vary slightly depending on the particular model, here are a general guide for using quick release fasteners:

- Preparation: Ensure that your components or panels are clear of any dust or debris, also make sure that the surface is completely dry.

- Positioning: Place the fastener body at the desired location and align it properly before attaching it.

- Insertion: Place your fastener into the slot or designated area, then secure accordingly, though most Fivetech fasteners allow tool-free installation, some models may require screwdrivers or wrenches to tighten it.

- Locking: If your chosen fastener model involves a locking mechanism, be sure to operate the knob or lever (plastic part) to engage the latch.

- Assessment: Apply pressure on the components or panels to make sure the fastener remains in place, also try out the disengagement mechanism to check if it functions properly.

- Regular Upkeep: To prevent issues during use, be sure to check the fastener and its components regularly for wear or damage. You may also have to clean the fastener and tighten any components when they become loose.

For more detailed instructions and visual guides, it’s always recommended to consult us or the user manual provided with your specific Fivetech quick release fastener model.

Quick Release Fasteners Industry Applications

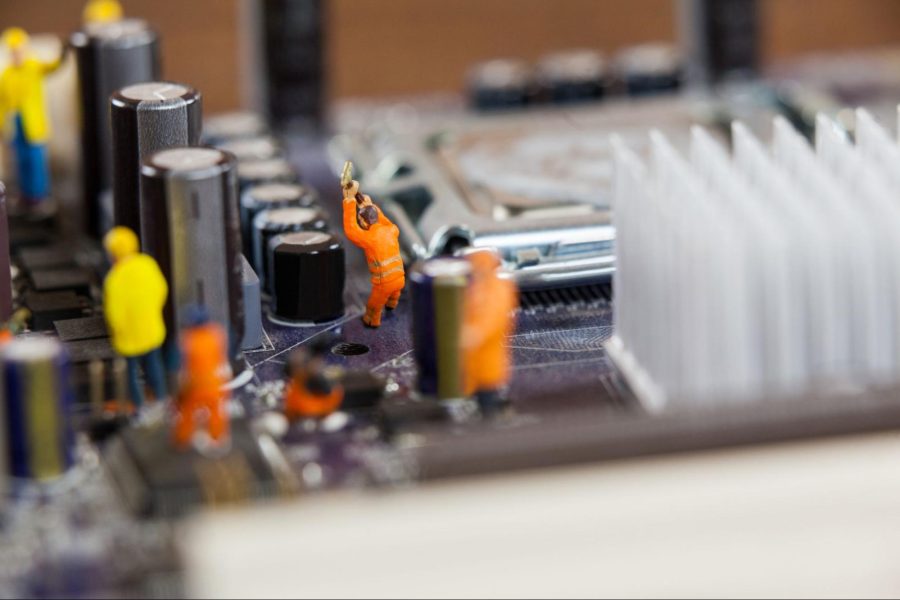

As we’ve mentioned, quick-release fasteners have a wide range of uses across many different industries. They’re common in the automotive, electronics, and aerospace industries, offering convenience and efficiency over traditional fasteners.

|

(Image by geargodz on Freepik) Automotive: In the automotive sector, they enable quick assembly and disassembly, crucial for efficient production lines and routine maintenance. Their ease of use reduces downtime, making them invaluable in fast-paced automotive environments. |

(Image by awesomecontent on Freepik) Electronics: These fasteners offer secure, yet easily accessible connections in electronic devices. Their adaptability is essential for rapid prototyping and frequent servicing of electronics, ensuring both security and ease of access. |

(Image by tongstocker1987 on Freepik) Aerospace: In aerospace, their reliability and weight-saving characteristics are critical. They ensure strong, yet lightweight connections, which are vital for the safety and efficiency of aircraft construction and maintenance. |

Why Should You Choose Fivetech?

Quick-release fasteners drastically cut down on time and manual labor, greatly boosting efficiency and transforming assembly methods in numerous industries. Fivetech stands out with its extensive range of innovative solutions, from quick-release screws to handle and roller systems, as well as specialized components like our PCB standoff, which are all ISO certified and RoHS compliant. Our commitment to quality and innovation ensures reliable and high-performing solutions for many mechanical needs. We also offer a stable and large-scale production, as well as timely delivery services to ensure uninterrupted supply and quick replacement to reduce your downtime. Even if you need special sizes or functions, we provide customization services to create tailor-made parts for your unique applications.

Ready to experience the convenience and efficiency of quick-release fasteners?

Click Here to make your design alive!

Take a Closer Look at Our Products

|

|

|

|---|---|---|

|

|

|