Folding handles offer an ergonomic solution to maximize space. Explore their unique handle types and their selection considerations in this article.

Are you tired of bulky, protruding handles that clutter your space and pose a safety hazard? Folding down handles offer a space-saving solution that improves functionality and safety in various applications, from server racks to network devices, medical equipment, industrial machinery, consumer electronics, and more.

This article will discuss the features and benefits of folding handles, helping you understand this unique component. We will also introduce different folding handle designs, materials, and installation methods so that you can find the right option for your specific needs.

1. Understanding Folding Handles

1.1. What are Folding Handles?

Unlike conventional handles that are fixed in position, folding handles feature a foldable design, so they can be retracted or collapsed when not in use, allowing them to lie flat against the attached surface.

1.2. How Do Folding Handles Work?

The folding mechanism varies for each handle design, but it typically involves sophisticated hinge systems, rotational mounts, or spring-loaded detents that help guide the handle’s movements. We’ll delve deeper into the different types of folding handles in the next section.

1.3. The Benefits of Folding Handles

The key advantage of folding handles is they conserve space. When not in use, they will remain flush on the attached surface to maximize the available space. This makes them particularly useful when space is limited or when a sleek, minimalist appearance is desired.

Moreover, folding handles can enhance safety, reducing the risk of injuries caused by protruding handles. As you fold them away, you can minimize the chances of people bumping into them and getting hurt.

These folding handles also provide a secure grip with their ergonomic design. Not only do they offer a comfortable feel during use, but they can also help to reduce strain and fatigue, particularly during extended or repetitive applications.

Additionally, folding handles offer great versatility. They can be installed on various surfaces, including drawers, server racks, machinery, and so much more! Plus, most folding handles are designed for quick and easy installation, often requiring only basic tools and minimal effort. Hence, they can be a practical and efficient solution for various applications.

2. Types of Folding Handles

Folding handles come in a variety of designs, each with a different mechanism for retracting or extending. By understanding these diverse options, you will be able to choose the most suitable folding down handle for your specific application.

2.1. Hinge Handles

Hinge handles, such as Fivetech’s 62 Series Handles, are the most basic and common type of folding handles. These handles typically come in a U-shape design and they feature a simple yet effective hinge mechanism that enables the handle to fold flat against the attached surface. Due to their simplicity, hinge handles are relatively straightforward to install and maintain. The hinge mechanism is also rather robust and durable, allowing long-lasting use.

2.2. Retractive Folding Handles

Retractive handles have specially designed hinges that automatically retract and fold flat on the connected components once the handles are released. They also prevent vibration and noise during transportation, reducing the risk of damage to delicate components.

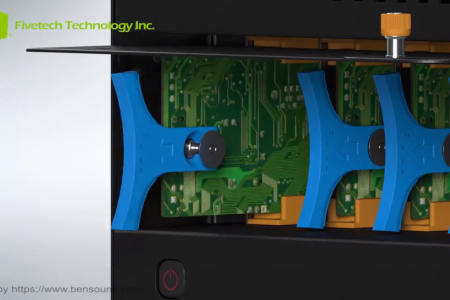

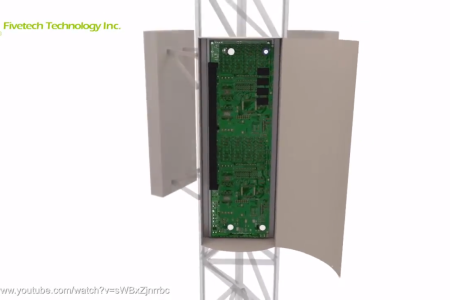

What’s more, some manufacturers offer retractive folding handles that are specifically made to bear high loads. As an example, a single 71 Series Handle by Fivetech can withstand up to 88 pounds (40kg) in weight. By installing four of these handles, you can even operate components as heavy as 352 pounds (160 kg)! You can watch this video to see how Fivetech’s high-load-bearing handles are used in real-world scenarios:

2.3. Smart Angle Handles

Smart angle handles combine a hinge mechanism and a spring-loaded system. Users can simply pull its latch to lift the handle upwards for operation. The handle can then be folded horizontally to be stored in a lateral 90° position.

Furthermore, the spring can be used to extend the handle outwards. This allows users to have more holding space or prevent accidental contact with other components by adjusting the handle length as required.

2.4. Smart Folding Handles

Smart folding handles incorporate a more complex spring mechanism within their hinge, allowing users to fix the handle at a 90° or 180° angle during operation. When secured in a lifted state, the handle provides a reliable grip when extracting components from data servers or other devices. After users are done, they can gently push the handle to return it to a folded position. The fixed angles also prevent the smart folding handles from swaying and reduce the risk of noise or accidental damage to the surrounding components.

2.5. T-Shaped Folding Pull Handles

Folding T handles offer convenient and efficient operation as the T-shaped structure can be easily lifted and pulled with two fingers. If it is no longer in use, the built-in spring structure can help users fold the T-shaped handle effortlessly, storing it in a flat position.

Furthermore, certain manufacturers also offer low-profile options for T-shaped folding handles. For instance, Fivetech’s low-profile folding handles feature a two-stage travel mechanism, allowing the T-shaped handle to be folded at a lateral 90° angle for even more compact storage. This model by Fivetech can also be combined with a latch lock system for added security and functionality. For visual insights into the capabilities and applications of Fivetech’s Low Profile Folding Handles, check out this video:

2.6. Ring Pull Handles

These pull handles feature a ring-shaped design that is easy to grasp and pull from any angle. They feature a spring-loaded mechanism. The spring will extend when lifted, providing users with more space to operate the handle. After releasing the handle, the spring will retract, returning the handle to a compressed state.

2.7. Round Pull Handles

Round pull handles have a compact knob-like design, which not only provides a comfortable grip, but also strengthens its force endurance. Similar to the ring pull handles, its telescopic structure can be effortlessly extended or retracted when necessary.

3. Materials of Folding Handles

Foldable handles are usually constructed from durable materials such as industrial-grade plastic or any metal that can withstand repeated use, even when exposed to harsh conditions. The materials should also provide resistance to wear and tear, ensuring long-lasting performance. Since each material has different properties, the best choice will depend on factors such as the intended application, required strength, and aesthetic preferences.

3.1. Plastic

Plastic folding handles can be made out of polypropylene (PP), acrylonitrile butadiene styrene (ABS), nylon, polybutylene terephthalate (PBT), etc, which are lightweight and cost-effective. They are corrosion-resistant so they can withstand harsh environmental conditions without losing their functionality or aesthetic appeal, further extending the lifespan of the folding handle.

Besides that, their unique texture offers a comfortable feel and secure grip at the same time, allowing the plastic folding handles to be more ergonomic. With their insulative properties, the plastic folding handles can also help minimize the risk of scalding and electrical hazards. Professional manufacturers like Fivetech even incorporate heat-resistant and fire-retardant PA9T nylon into their folding handle design, taking safety and durability to the next level.

3.2. Metal

Some common metal materials used for folding handles include:

Stainless Steel: This metal alloy is widely used for folding handles due to its high corrosion resistance and durability. It can offer long-lasting performance despite exposure to humidity, changing temperatures, and other harsh conditions.

Carbon Steel: While not as corrosion-resistant as stainless steel, carbon steel is a strong and malleable metal that is cost-effective, so it is one of the most commonly used metals for folding handles.

Aluminum: Lightweight and corrosion-resistant, aluminum is suitable for applications where weight reduction is a priority. Although it may not be as strong as steel, it still offers a great strength-to-weight ratio, as well as electrical and thermal conductivity.

In addition to the base material, metal folding handles can be finished with zinc or nickel coatings to enhance their properties. Zinc coatings are preferred when the application requires more corrosion resistance, while nickel coatings can offer more hardness and wear resistance.

4. Folding Handle Mounting Methods

To install a folding handle, you must first decide whether or not a mounting plate is required. A folding handle with a mounting plate consists of a flat metal plate with pre-drilled holes for the fasteners to be inserted. If a mounting plate isn’t necessary, thread-in smart folding handles can be used instead. This option allows users to install folding handles directly onto the targeted surface.

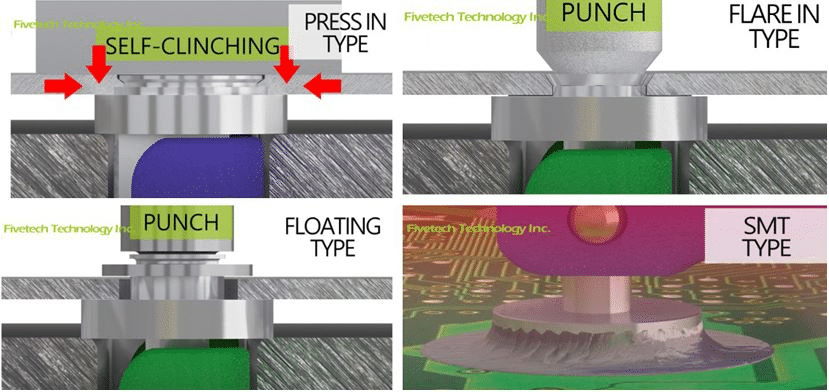

Then, the folding handle can be mounted securely onto the targeted surface either with press-in, flare-in, floating, or SMT techniques.

4.1. Press-In Method

To install press-in smart folding handles, they must be forced into pre-drilled holes in the mounting surface. The handle’s self-clinching mechanism will then cause the surface material to deform and cold flow around the handle, creating a secure bond.

This method is simple and efficient, so users can mount the folding handle with minimal effort. However, the material thickness on the mounting surface must be considered. If it is too thin, there might not be enough material to secure the folding handle. This may cause the handle to loosen or fall off during operation, compromising its safety.

4.2. Flare-In Method

Flare-in is a method that involves inserting a folding handle into a pre-drilled conical hole in the mounting surface. As the flare-in folding handle is inserted, the ferrule of its fastener will be deformed, creating a flared lip that grips the interior walls of the hole. This method is ideal for thin or delicate materials, as it doesn’t deform the targeted surface. It will also create a flush finish, providing a clean and aesthetic appearance.

Manufacturers like Fivetech also offer flare-in folding handles with pin lock features. The carbon steel pins will extend when mounted, aligning seamlessly with the surface panels. This integrated latch lock system ensures a secure and user-friendly installation.

4.3. Floating Method

Floating is a method that involves using a washer or spacer between the folding handle and the mounting surface. This allows for slight movement between the handle and the surface, enabling the floating handle to absorb tolerance and provide flexibility for small misalignments, which is beneficial for applications that require exposure to vibrations in industrial machinery, data centers, and manufacturing equipment.

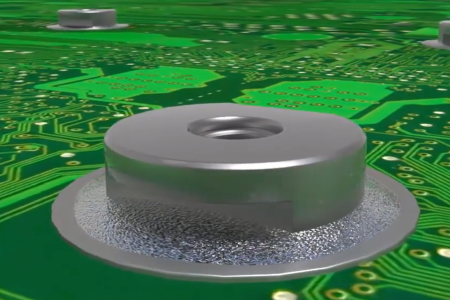

4.4. Surface Mount Technology (SMT)

SMT smart folding handles can be attached directly to a printed circuit board (PCB) through automated processes. It involves solder paste printing, folding handle placement with pick-and-place machinery, and reflow soldering which will create a strong bond.

The automated equipment used for SMT significantly increases production speed and reduces labor costs. It can also ensure precise placement of the foldable handles, minimizing errors and defects.

5. Measurements to Consider for Selecting Folding Handles

By carefully considering the following factors, you can select folding handles that are the right size and dimensions for your specific application, ensuring optimal performance and functionality:

Handle Length: This refers to the handle’s overall length from one end to the other. This dimension is important for determining the reach and leverage provided by the handle. A longer handle can offer more leverage, while a shorter handle may be more compact and easier to maneuver in limited spaces.

Handle Height: The handle height, also known as projection, is the distance the handle extends from the mounting surface when fully extended. Ensure that the handle height is compatible with the available space and does not interfere with other components or objects.

Mounting Hole Spacing: Also known as pitch. The distance between the mounting holes on the folding handle should match the spacing on the mounting surface for a secure and aligned installation.

Handle Width: The width of the handle, also known as diameter, is important for comfort and ease of use. Select a handle width that is suitable for the intended application and the size of the user’s hands.

Angle Degree: Consider the desired angle to ensure it meets your specific needs. Though most folding handles maintain a fixed angle when they are lifted or folded, some folding handles also offer adjustable angles, allowing you to customize the position of the handle.

Thread Size: The thread size of the folding handle is crucial for compatibility with the mounting surface, so you must make sure that the thread size matches the pre-tapped holes or threaded inserts in your application.

6. Discover the Best Folding Handles at Fivetech

With space-saving benefits and an ergonomic design, folding handles serve as a practical solution to enhance functionality and safety across various industries. As a leading manufacturer of high-quality folding down handles, Fivetech offers a wide range of ISO-certified and RoHS-compliant products designed to meet the diverse needs of our customers.

If you can’t find a suitable option in our comprehensive folding handle catalog, our team of experts can work with you to develop customized solutions with sizes, colors, materials, and other design features tailored to your specific requirements. Visit Fivetech today to discover more!

Seeking the product for your challenging applications?

You May Also be Interested in

➤ Fivetech’s Captive Screws and Fasteners

➤ Ultimate Guide to Captive Screws: Types & Applications

➤ Quarter Turn Fastener – Fivetech

➤ Fivetech Quick Release Fastener | All Solutions

➤ Discover M.2 Board Latches: The Perfect M.2 Screw Alternative

➤ Mastering PCB Standoffs: A Comprehensive Guide to SMT Solutions

➤ Understanding Server Hardware & Its Main Components – Fivetech

➤ How to Measure Screws, Bolts, and Threads Sizes – Fivetech

➤ Fivetech’s Thumb Screws: Convenient and Reliable

➤ Exploring Riveting Machines: Advantages, Types, and Selection Tips – Fivetech