PCB standoffs are vital for securing and supporting Printed Circuit Boards (PCBs). They help improve heat dissipation and allow for quicker positioning in PCB boards, reducing the damage to the circuit during assembly. In this article, we will explore their importance, types, and applications while focusing on SMT standoffs, their role in electronics, and how Fivetech’s innovative designs provide unique advantages for modern industries.

1. PCB Standoffs and Complementary Components by Fivetech

By holding PCBs firmly in place, PCB standoffs can establish secure connections between PCBs, components, and other hardware elements while maintaining optimal space between them.

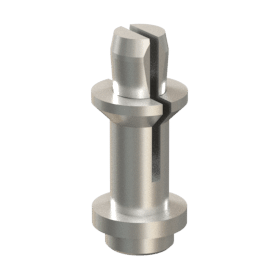

Unlike conventional PCB board standoffs that have thread specifications such as M2, M2.5, M3, M3.5, M4, M6, 4#40, 8#32, or 6#32 threads, Fivetech offers a unique solution with our high-quality unthreaded SMT standoffs which can be installed with a quick and secure snap-in mechanism. This ensures compatibility with different hardware and simplifies assembly to improve production efficiency.

These SMT standoffs can also be paired with other components to enhance functionality and design flexibility. Options include nuts for strong grips, guide pins for precise alignment, spools for flexible PCB arrangement, or spring locks for secure fastening. With this in mind, here is a brief overview of the components available on Fivetech:

| Product (Click to Purchase) |

Threaded / Unthreaded | Thread Size | Mounting Method on PCB | Gender (Thread Type Classification) | Body Material | Finish |

|---|---|---|---|---|---|---|

| SMT Standoff | Unthreaded (Snap-in) | – | SMT | Male | Brass | Tin |

| SMT Spacer | Threaded | M3*0.5 thread | SMT | Female | Carbon steel | Tin |

| 82 Series SMT Nut | Threaded | M2x0.4 thread | SMT | Female | Carbon steel | Tin |

| High Torque SMT Nut | Threaded | M5x0.8 thread | SMT | Female | Carbon steel | Tin |

| SMT Floating Nut | Threaded | M4x0.7 thread | SMT | Female | Stainless steel | Natural |

| SMT Stud | Threaded | M5*0.8 thread | SMT | Male | Brass | Tin |

| SMT Guide Pin | Unthreaded | – | SMT | Male | Carbon steel | Tin/Zinc |

| SMT Spool | Unthreaded | – | SMT | Male | Carbon steel | Tin |

| SMT Spring Lock | Unthreaded | – | SMT | Male | Carbon steel, Stainless steel | Natural |

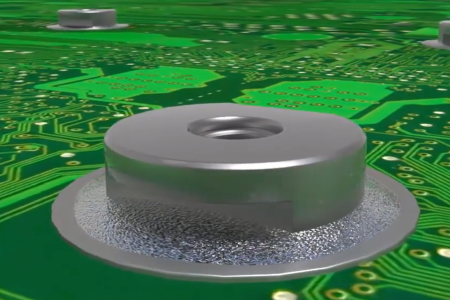

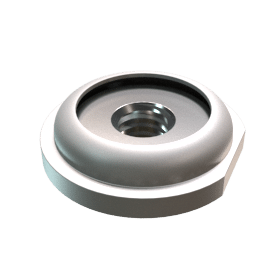

SMT Standoff:

The SMT standoff features a snap-in design so it compresses during insertion into a pre-drilled hole on the PCB and expands outwards to secure the standoff in place once it passes through, eliminating the need for additional screws. Its body/barrel will then help maintain a distance betweenthe PCB and other components within the chassis, providing support and stability.

Fivetech’s SMT standoff can also be mounted directly onto PCBs using a fully automated process with pick-and-place machines, solder printers, and reflow ovens. The accurate assembly equipment helps minimize the risk of PCB damage during assembly, further improving product reliability.

SMT Spacer

Fivetech’s SMT spacers provide elevation and support for PCBs, similar to our SMT standoffs. However, they feature internal threads, enabling secure PCB fastening with screws. This allows for enhanced stability and a more robust connection in applications that require greater holding power. The SMT spacer can also handle the high temperatures involved with SMT processes, offering production efficiency through automated assembly.

82 Series SMT Nut :

The 82 series SMT Nuts by Fivetech are engineered with internal threads to mate with screws, effectively preventing axial movement to create robust connections. This threaded design allows the nut to be easily tightened after prolonged use or vibration, preventing loosening and ensuring consistent fastening strength. and can be easily retightened after prolonged use to maintain consistent fastening strength.

While manual assembly is possible, these SMT nuts may be mounted through automated SMT for precise placement and strong solder joints, enhancing the overall reliability of the components. We also offer customization options and various specifications for our SMT nuts, making them a versatile choice for different applications.

Floating Nut:

Fivetech’s floating nut stands out due to its unique two-piece design. Not only does it maintain advantages in anti-rotation and preventing vibration-induced loosening, but it also offers space for screw float, broadening its range of applications.

Its automated manufacturing process enhances efficiency, while the bottom square anti-rotation design enhances locking performance, making it suitable for various applications. For a visual insight into its design, watch the video: Fivetech Technology Inc.- SMT Floating Nut.

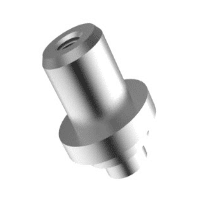

SMT Stud

This SMT Stud can be soldered to a PCB, providing a threaded post for attaching another component. It also features a square base design that prevents rotation during installation and provides increased torque resistance. This creates a more secure and reliable connection. Additionally, unlike traditional screw and nut combinations, SMT studs can be soldered directly to the board, eliminating manual assembly steps and reducing the risk of loose parts.

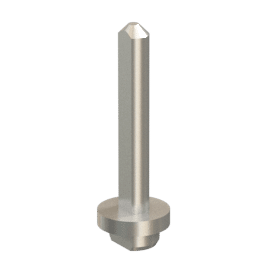

SMT Guide Pins:

SMT guide pins are not only pivotal for enhanced production stability and efficiency through their fully automated reflux welding process but also play a vital role in alignment. Ideal for vertically oriented board mounting, they ensure that different modules can be conveniently and accurately positioned in their designated locations. This precise alignment boosts assembly operation efficiency. Furthermore, the option for welding and reinstallation contributes to increased product reliability and ease of maintenance.

Fivetech’s comprehensive selections for this category include basic SMT guide pins, 85 Series SMT Guide Pins with a two-part system for accurate alignment, SMT Guide Pin with M2 threads for compact applications, and SMT Angle Guide Pins that allow anti-rotation positioning.

SMT Spools:

SMT spools are multifaceted in their functionality. Beyond streamlining assembly processes and providing quick-release features, the unique Double SMT Spool design assists in elevating multiple PCB boards. This elevation not only enhances airflow between layers but also aids in achieving effective heat dissipation.

These spools contribute to production stability and efficiency, thanks to the SMT fully automated manufacturing process. Their lateral fastening capability is tailored for direction-limited panels, further simplifying assembly and boosting reliability. Discover more about how SMT spools differentiate themselves in this video: Fivetech Technology Inc.-SMT Spool Application.

Watch how SMT spools stand out in this video: Fivetech Technology Inc.-SMT Spool Application.

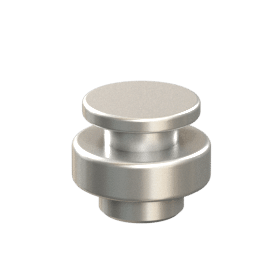

Spring Lock:

Spring locks are designed with an innovative anti-loose function, the SMT Spring Lock effortlessly combines two plates while delivering a reliable clamping force, ensuring a secure and sturdy connection. It can also be used to connect the PCB board and the metal surface of the server chassis, reducing collisions with plates.

Fivetech’s SMT guide pins, SMT spools, and spring locks offer comprehensive support for electronic assembly processes. With automated manufacturing processes and reinstallation capabilities, these components enhance production stability, improve product reliability, and contribute to efficient assembly operations.

2. Benefits of Using PCB Standoffs

PCB board standoffs offer several benefits to electronic systems’ overall functionality and reliability, including:

- Overheating Prevention: Standoffs ensure proper spacing between the PCB and the mounting surface, promoting adequate airflow and heat dissipation. This helps prevent overheating and improves the overall thermal management of the system.

- Mechanical Stability: PCB board standoffs also provide structural support, preventing PCB flexing, warping, or damage caused by vibration, shocks, or mechanical stress. This enhances the mechanical stability and longevity of the electronic assembly.

- Electrical Isolation: By maintaining space between conductive metal surfaces, standoffs can minimize the risk of electrical interference among PCB components, thus preventing short circuits.

- PCB Protection: By lifting the PCB off the mounting surface, standoffs safeguard against potential damage from spills, moisture, and contaminants.

3. How to Choose the Right PCB Standoff for Your Needs

Material compatibility, thread type, size, height, and load-bearing capacity should all be considered when choosing PCB board standoffs to ensure proper installation and effective performance.

To help you make informed decisions, we’ll introduce the common types of PCB standoff materials, threads, and designs below.

3.1. Materials Used in PCB Standoffs

PCB standoffs are available in various materials, each offering unique properties and advantages. For instance, metal standoffs, such as those made of brass, steel, or aluminum, are preferred for applications that require heat-resistant properties or conductivity.

On the other hand, despite being less strong, board standoffs made with insulative, non-conductive materials such as nylon or ceramic may be used for minimizing electrical shocks and other safety hazards.

Here are more details about the most common PCB standoff materials:

- Brass PCB standoffs are known for their corrosion resistance and excellent electrical conductivity, making them ideal for applications requiring reliable grounding and signal transmission. Brass is also easily machinable, allowing for precise tolerances in critical components.

- Carbon steel standoffs are the most cost-effective options. They also provide exceptional strength and mechanical support, making them suitable for heavy-duty applications. However, they are susceptible to corrosion unless treated with a protective coating.

- Stainless steel standoffs are pricier but combine strength, corrosion resistance, and durability. This makes them ideal for applications exposed to harsh environments or requiring long-term reliability.

- Aluminum PCB standoffs are lightweight yet strong, offering a high strength-to-weight ratio. They are also corrosion-resistant and have good thermal conductivity, making them a cost-effective choice for applications where weight and heat dissipation are concerns.

- Nylon or plastic PCB standoffs are excellent electrical insulators ideal for preventing electrical hazards. They are also lightweight, chemical resistant, and dampen vibration. Nevertheless, nylon can absorb moisture, making it unstable in humid environments.

- Ceramic PCB standoffs offer exceptional electrical and thermal insulation, making them suitable for high-temperature and high-voltage applications. They are also chemically inert and resistant to wear but they are more brittle than metals and plastics, making them more susceptible to impact damage

Understanding the characteristics of different standoff materials helps select the appropriate one for specific PCB design and assembly requirements.

3.2. Thread/Gender Types of Board Standoffs

If you are considering threaded board standoffs, it is important to note that they are available in three gender types — female-female, male-female, or male-male, which are categorized by the type of threads on each end.

- Female-Female Standoffs: These standoffs feature internal (female) threads on both ends. They are essentially threaded spacers, allowing screws or male-threaded components to be attached to either side. Shorter female-female standoffs are typically fully threaded, while longer ones have threads only at the ends. They are commonly used to create a fixed distance between two components, such as PCBs on a chassis.

- Male-Female Standoffs: These standoffs have external (male) threads on one end and internal (female) threads on the other. This is particularly useful for stacking PCBs or mounting a component to a surface with pre-tapped holes. The male end threads into one component, while the female end receives a screw to secure the other component. This reduces the number of fasteners required and simplifies assembly.

- Male-Male Standoffs: These standoffs have external (male) threads on both ends. They are used to connect two components with female threads. Male-male standoffs can also function as thread adapters, converting a female thread to a male thread of the same or different size. This provides flexibility in connecting components with mismatched thread types.

3.3. Different Design Types of PCB Standoff

Surface-mount threaded (SMT) standoffs, also commonly referred to as “SMT nuts” or “Spacers,” find wide-ranging applications in various electronic systems and assemblies. Along with nuts, studs, spools, and guide pins, these versatile components are extensively used in PCB assemblies, electronic device enclosures, panel mounting, and component positioning.

PCB standoffs also come in various designs catering to different applications and assembly needs. Standard/Pin Standoffs, like the ones provided by Fivetech, are the most common type of PCB. Their shape is typically cylindrical or hexagonal, making them easy to tighten. They can be any of the gender types mentioned above with either male-female, female-female, or male-male threading. They provide a simple, rigid connection for spacing and mounting PCBs.

Furthermore, their simplicity translates to several key advantages:

- Cost-Effectiveness: Their straightforward design and manufacturing process make them a highly economical solution for most PCB mounting needs.

- Wide Availability: Due to their widespread use, standard standoffs are readily available in various sizes, materials, and thread types, offering flexibility in design and sourcing.

- Ease of Use: Their standardized shapes allow for quick and simple installation with common tools, simplifying assembly processes.

- Reliable Performance: While lacking the specialized features of other designs, standard standoffs provide a robust and dependable connection for static mounting applications, effectively maintaining spacing and preventing short circuits.

Even though other specialized standoff designs offer unique advantages for specific applications, they often come with increased complexity, cost, and limited availability. Nevertheless, we’ve compiled an overview of these different standoffs to help you gain a general understanding:

- Rounded Standoffs: Unlike standard standoffs with sharp edges, rounded standoffs have a curved profile. This design is primarily for safety, reducing the risk of cuts or abrasions during handling and assembly. They are also suitable for mounting fragile components as the rounded surface distributes pressure more evenly.

- Tapered Standoffs: These standoffs have a conical shape, which aids in precise alignment during assembly. The tapered design guides the mating component into the correct position, ensuring accurate placement and reducing the risk of cross-threading. They are often used in applications requiring tight tolerances and accurate component positioning.

- Spring-Loaded Standoffs: These standoffs incorporate a spring mechanism, providing flexibility and dynamic movement. They are particularly useful in applications where shock or height variations are concerns. The spring absorbs vibrations and allows for slight height adjustments, maintaining a secure connection even under dynamic conditions.

- Rotating/Swivel Standoffs: These standoffs incorporate a swivel mechanism such as ball bearings between the threaded ends. This allows for rotational movement and flexibility, accommodating misalignment between components or dynamic movement during operation. They are useful in applications where precise alignment is difficult or where some degree of movement is expected.

- Tooling Ball Standoffs: These standoffs feature a steel ball at one end, providing enhanced flexibility and movement for positioning and aligning components. The ball allows for smooth adjustments and can be interchanged to accommodate different ball sizes. They are commonly used in fixturing, clamping, and other applications requiring versatile positioning and alignment capabilities.

Due to Fivetech’s commitment to providing reliable and readily available solutions with competitive pricing, we mainly offer pin standoffs which is an ideal choice for a broad spectrum of PCB applications. If you need unique components or measurements for your specific application, you can also contact us to discuss your customization requirements.

4. Applications of Standoffs in Electronics and Telecommunications

Surface-mount standoffs are widely used in electronic and telecommunications equipment. They can be found in various circuit designs, from mobile devices to telecommunication networks, embedded systems, industrial controllers, and medical equipment.

However, some of their applications in electronic and telecom equipment include:

- Mounting PCBs:

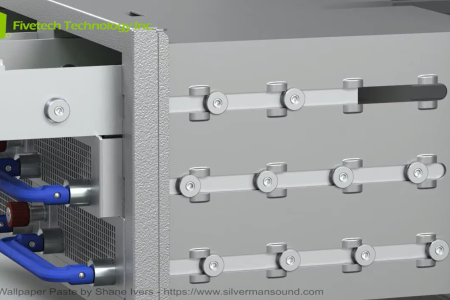

In mounting printed circuit boards (PCBs), SMT standoffs ensure stability, spacing, and support for components. Securely holding the PCBs in place prevents shifting and reduces the risk of damage caused by vibrations or mechanical stress. This is essential for maintaining the integrity and functionality of electronic systems.

- Securing Electronic Enclosures:

Beyond PCB mounting, SMT standoffs find application in securing electronic enclosures. They contribute to proper alignment, preventing misalignment or misfitting that can compromise the overall structure. This ensures the protection and longevity of the enclosed electronic components.

- Wire Management and Routing:

SMT standoffs also play a crucial role in wire management and routing within electronic devices. They facilitate organized and efficient wiring, promoting optimal signal transmission and reducing the risk of signal interference or short circuits.

Fivetech provides video previews of their solutions in action to further illustrate the practical applications of SMT standoffs. These include demonstrations of SMT Captive Screws and SMT Nuts for AI, Electronic Car Fastening Solutions, and the application of SMT Studs and Pins on motherboards. These videos showcase the versatility and effectiveness of SMT standoffs in real-world scenarios.

SMT standoffs are indispensable components that ensure electronic and telecommunications systems’ reliability, functionality, and longevity.

5. Future Developments in PCB Standoffs

The field of PCB standoffs is continuously evolving, with emerging technologies and materials poised to shape the future of these components.

Expected Advancements:

Advancements in manufacturing processes are driving improvements in production efficiency and quality. As PCB and board design trends evolve, standoffs will adapt to meet new requirements, such as miniaturization, increased functionality, and enhanced performance.

Fivetech’s dedicated team is actively involved in research and development to provide more effective and innovative standoff solutions that cater to the evolving needs of the electronics industry. Exciting developments lie ahead, promising even more optimized and reliable PCB standoff options.

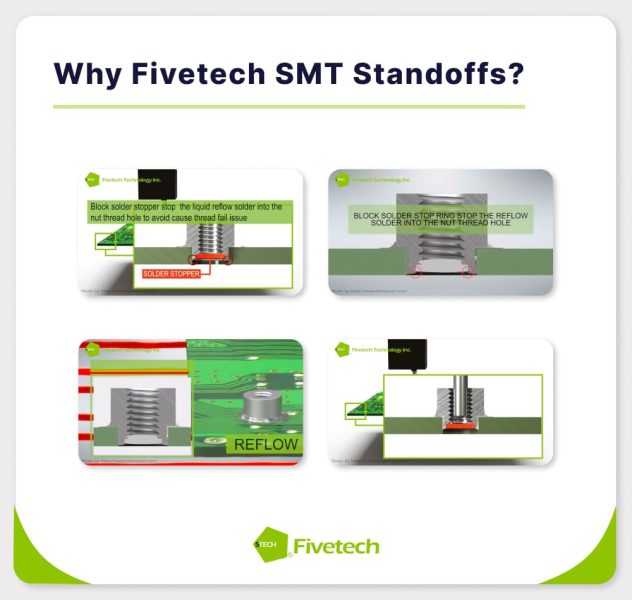

6. Conclusion: Why Fivetech SMT Standoffs?

In conclusion, Fivetech SMT Standoffs offer a comprehensive range of advantages, making them a preferred choice in the electronics and telecommunication industry.

Why Us?

We provide a complete product line of SMT PCB standoffs, catering to different sizes and shapes, ensuring that customers can find the perfect standoff solution for their specific requirements. With mold development capabilities, Fivetech reduces costs and offers customized options, including thread types, riveting forms, and material choices.

Tailored to meet specific client needs and improve compatibility, our SMT Standoffs are designed to align closely with client operations, ensuring seamless integration and optimal performance.

100% highly soldering reliability:

Our SMT patent technology introduces the innovative Solder Stop Ring, a standout feature found in our high-torque SMT nuts. This technology addresses multiple concerns, improving both reliability and longevity:

- Stop Ring Protection: The stop ring prevents thread damage caused by the inflow of tin during the SMT reflow process.

- Enhanced Reliability: It ensures 100% high soldering reliability. By preventing thread damage from tin inflow— which might result in solder paste existing between the PCB and outer standoff/nut flowing to the inner side, and potentially causing unstable reliability or other concerns— it reduces the chances of failure and associated rework costs.

- Efficiency in Pick-Up: Compared to manual peeling of mylar, our stop ring aids the vacuum nozzle in automatically picking up standoff/nut components, cutting down on manual labor costs.

Fivetech’s extensive range of products includes quick-release fasteners, captive screws, thumb screws, quarter-turn fasteners, folding handles, M.2 board latches, and more components compatible with various installation methods! Visit our homepage to learn about our offerings. Additionally, check out our YouTube videos for visual insights into the capabilities and applications of our SMT Standoffs.

Transform your assembly process with Fivetech now!