Home » By Category » Captive Fastener

What is a captive screw? Captive screws are essential hardware used in many applications. Unlike conventional screws, they remain attached to the panel even when unscrewed, preventing loss and mishaps in machinery, which makes it a safer, more reliable, and foolproof solution. There are many assembly types for captive screws, such as press-in, flare-in, floating, and SMT captive screw installation.

Visit Fivetech’s homepage now to discover a wide range of fastener options, such as captive panel screws and thumb screws. With our excellent captive screw designs, it is guaranteed to find the perfect captive screws for your needs.

Choosing the right material for your captive screws ensures optimal performance in their specific applications. So, on top of cost, be sure to consider whether your captive screw will be exposed to moisture, chemicals, or extreme temperatures. You should also regard the load it has to withstand to select the right material.

We offer a variety of strong and durable metal materials for our captive screws, including carbon steel, aluminum, brass, and stainless steel, while certain models incorporate heat-resistant and fire-retardant plastic to create user-friendly knobs on the screw head.

Fivetech’s captive screws are crafted from various alloys, including those based on carbon steel, aluminum, brass, and stainless steel, allowing us to provide balanced properties that can be tailored to different applications. For instance, carbon steel offers cost-effectivness and strength, while stainless steel is as a premium option exceptional corrosion resistance and durability. Aluminum are known for their lightweight properties and great strength-to-weight ratio, whereas brass provides good conductivity and corrosion resistance despite being heavier. By combining these metals into alloys, we can enhance the overall strength, durability, or other specific properties of the captive screws.

In addition to metal alloys, certain captive screw models incorporate heat-resistant and fire-retardant plastics for the knob. Not only are they lightweight and cost-effective, but they also a better grip and good insulation, thus reducing the risk of scalding and electrical hazards. These materials enhance user safety and product performance in specific applications.

The knob style of your captive screw not only affects aesthetics, but also its overall functionality. The options offered by Fivetech includes, round knobs, square knobs, and wing knobs, which all can be operated by hand, eliminating the need for tools.

For unique requirements, Fivetech offers customized knob shapes and sizes to match your needs. Whether you need a larger knob for better visibility or a smaller knob for tight spaces, our customization options ensure a perfect fit.

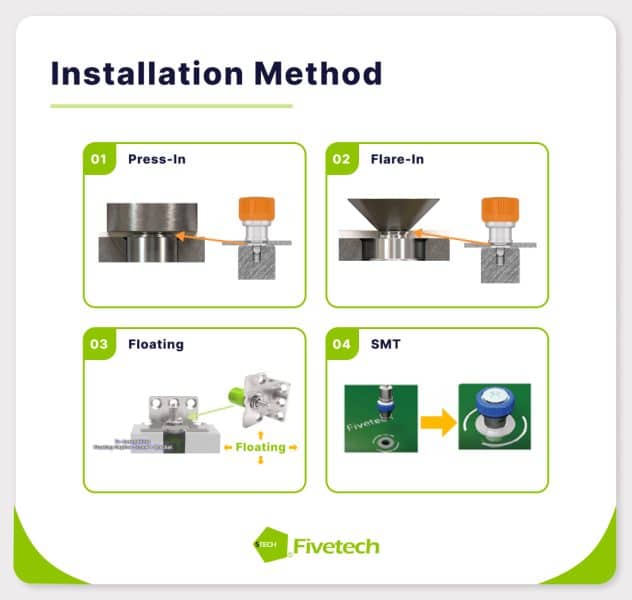

Fivetech offers captive screws with press-in, flare-in, floating, and surface mount technology (SMT) installations, so that you can secure the captive screws firmly to the metal sheets or PCBs. This prevents the screws from loosening or falling into the equipment, reducing the risk of malfunctions. Installing the screw directly onto the panels also makes it easier to operate without tools.

Press-in captive screws offers a offer a fast, secure installation for electronics, automotive, and industrial applications. They are inserted forcefully into pre-drilled holes, deforming the panel material around the screw to create a sturdy bond. Though press-in is versatile with various panel thicknesses, material compatibility should be considered. Iron is ideal, while steel and aluminum might need testing to ensure suitability. Plastic and PCBs should be avoided with this method as it can lead to cracks or fractures.

Flare-in installation involves drilling a conical hole in the panel. The ferrule will then be deformed as it passes through this hole, creating a grip without affecting the panel, making it suitable for a wider range of materials, as long as the panels have the right thickness. It also offers a flush finish, so it is often used in applications where aesthetics are important, such as consumer electronics and automotive interiors.

In contrast, floating captive screws are fitted with a washer before being secured to the panel using a press. The washer leaves a space for slight movement to absorb tolerance and accommodate small misalignments, which can be beneficial for applications requiring flexibility and vibration resistance, such as industrial machinery, data centers, and manufacturing equipment.

Lastly, our SMT captive screws are designed to be soldered directly onto the printed circuit boards. They offer a reliable and automated installation ideal for high-volume electronic manufacturing with PCB processes.

Though the standard option has a balanced profile suitable for most applications, we also offer low-profile designs that feature a shorter stroke or travel distance. This allows seamless integration into compact designs of electronic devices and enclosures, without compromising security and functionality. It also offers finer control and more accurate positioning for applications that require high precision and small-scale adjustments. Additionally, the short travel distance can achieve faster response times as well as higher operation frequency, making them well-suited for high-speed automation and electronic devices.

By carefully considering the environmental conditions of your application and selecting the appropriate captive screw, you can ensure the reliability and longevity of your equipment, especially since factors such as operating temperature and oxidation can significantly impact the lifespan of these fasteners.

Catering to diverse applications, Fivetech offers a wide range of heat-resistant metal and fire-retardant plastic for our captive screws to boost their resilience and resistance against oxidation. A protective zinc finish is also applied to some of our captive screws to further enhance oxidation resistance, aesthetics, and overall durability. We offer captive screws with a nickel finish as well, boosting its resistance against corrosion and abrasion.

For applications that involve SMT, our products can withstand up to 260°C for high-temperature soldering, allowing a streamlined mounting process and secure connection. We also offer matte tin plating for our SMT products to further enhance solderability and prevent whiskering. Moreover, our captive screws have undergone rigorous assessment, including pull/push force, torque, salt spray testing, etc, guaranteeing their performance in demanding environments.

Furthermore, due to the intensive computational processes involved, AI servers generate high thermal loads, causing the cooling system and power supply components to reach elevated temperatures. To ensure the reliability and performance of these servers, it is essential to leverage components, including captive screws, that can withstand prolonged exposure to heat without compromising integrity. The fire-retardant plastic of the captive screw knobs also minimizes the risk of burns from these hot surfaces.

Fivetech’s captive screws provide a secure fastening solution to ensure consistent performance and reduce downtime in various applications, including:

You May Also be Interested in

➤ Ultimate Guide to Captive Screws: Types & Applications

➤ Quarter Turn Fastener – Fivetech

➤ Fivetech Quick Release Fastener | All Solutions

➤ Discover M.2 Board Latches: The Perfect M.2 Screw Alternative

➤ Mastering PCB Standoffs: A Comprehensive Guide to SMT Solutions

➤ A Guide to Folding Handles: Embracing Compactness and Functionality

➤ Understanding Server Hardware & Its Main Components – Fivetech

➤ How to Measure Screws, Bolts, and Threads Sizes – Fivetech

➤ Fivetech’s Thumb Screws: Convenient and Reliable

➤ Exploring Riveting Machines: Advantages, Types, and Selection Tips – Fivetech

End of content

No more pages to load

Please leave your brief messages and contact information.

We will be back to you as soon as possible.