| Table of Contents: |

| How to Measure Screw Sizes |

When purchasing screws, you may be confused about how to measure the screw size.

To prevent such issues, it’s essential to comprehend how screws are measured and master the art of measuring screw size. Additionally, grasping how to determine bolt size is equally crucial. Fortunately, measuring screws is a straightforward task, requiring only a measuring tape or ruler and the screws in question. Just remember to measure the screws accurately, considering whether they are listed in the imperial system or metric system on the packaging.

Screw / Bolt Size Measurement

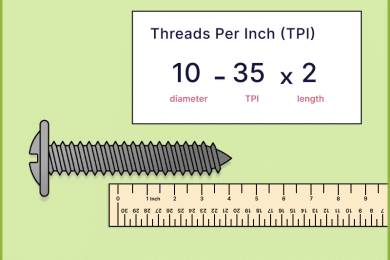

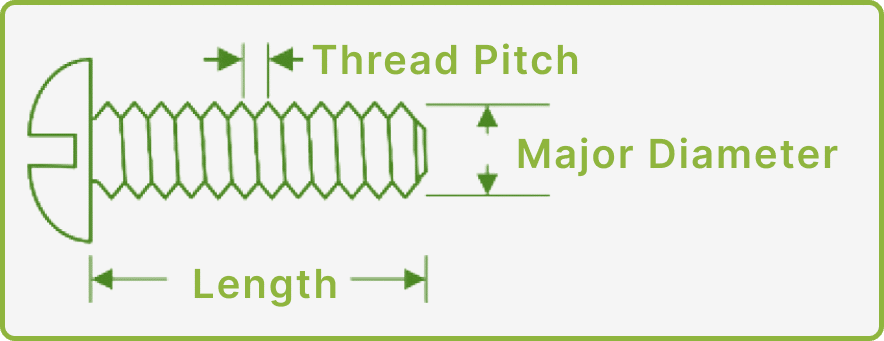

When it comes to identifying screws and bolts, there are several key parameters for screw size measurement: diameter, length, and thread pitch.

- Diameter is determined by the major and minor diameters. For screws with a thickness of 1/4″ or smaller, their sizes are typically represented by a number, referred to as a nominal measurement.

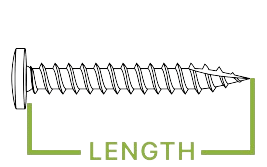

- Length is typically measured from the head to the tip of the thread. Each type of fastener, such as hex, pan, button, socket cap, and round head screws, is measured from the different parts of the head to the tip. Check the content below to know how to measure screw length size.

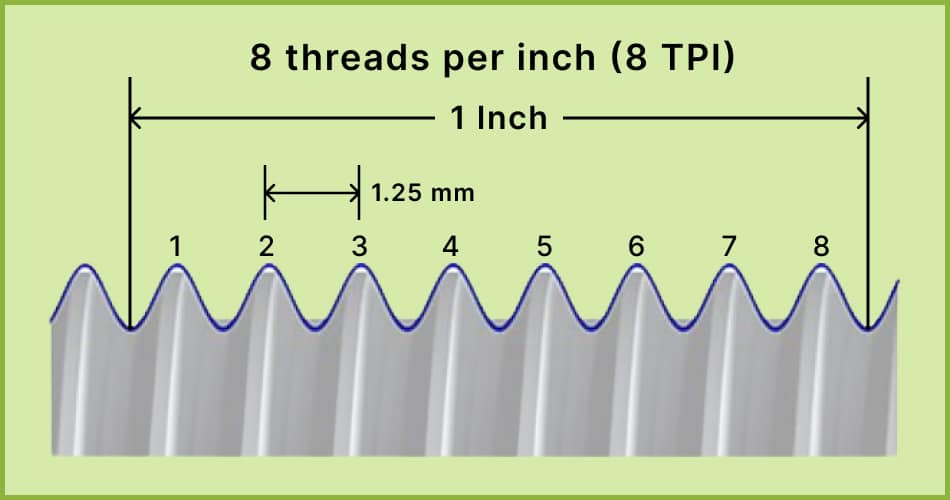

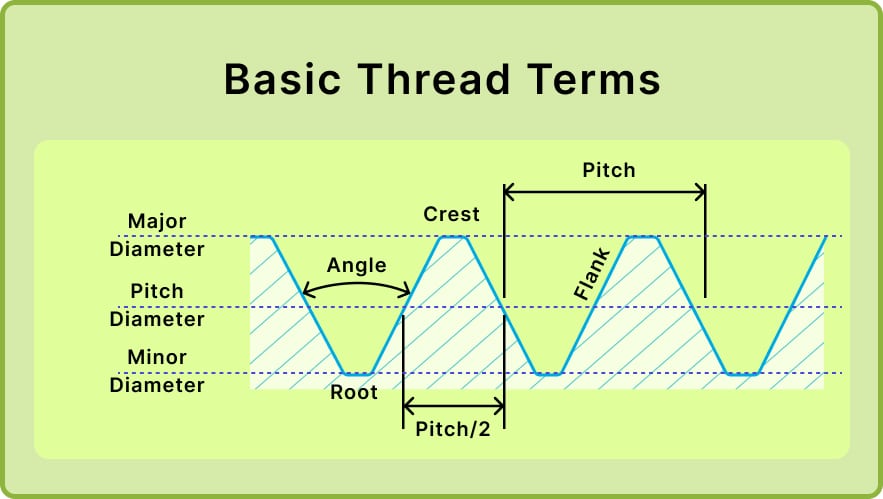

- Thread pitch refers to the distance between each thread on a screw, and can be measured from any point, whether it’s the top (crest), bottom (trough), or anywhere in between.

Diameter of Screws / Bolts

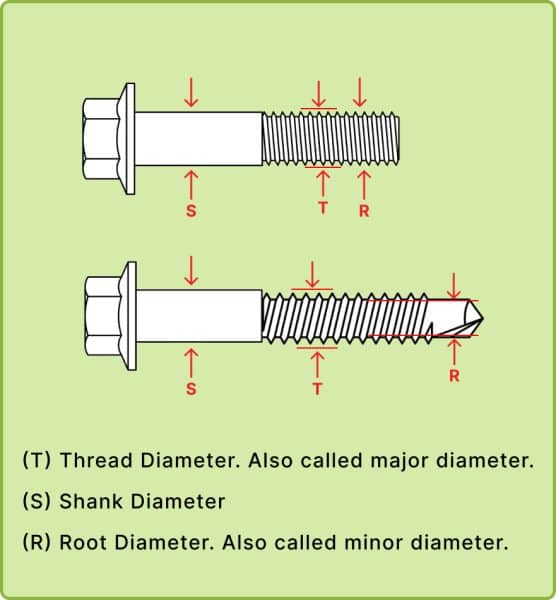

Major and Minor diameters are two rules to measure screw size/bolt diameter.

- The major diameter is the distance across the outermost threads from one side to the other.

- The minor diameter is the distance across the lowest part of the thread’s groove from one side to the other.

For sizes 1/4″ or smaller screw thickness, sizes are often indicated by a number, known as a nominal measurement. The table contains these numbers and their corresponding decimal equivalents.

| Screw Size | Fractions | Decimals | Millimeter |

| #1 | 1/16″ | 0.0625″ | 1.5875 |

| #2 | 5/64″ | 0.078125″ | 1.98437 |

| #3 | 3/32″ | 0.09375″ | 2.38125 |

| #4 | 7/64″ | 0.109375″ | 2.77812 |

| #5 | 1/8″ | 0.125″ | 3.175 |

| #6 | 9/64″ | 0.140625″ | 3.57187 |

| #8 | 5/32″ | 0.15625″ | 3.96875 |

| #9 | 11/64″ | 0.171875″ | 4.36562 |

| #10 | 3/16″ | 0.1875″ | 4.7635 |

| #11 | 13/64″ | 0.203125″ | 5.15937 |

| #12 | 7/32″ | 0.21875″ | 5.55625 |

| #13 | 15/64″ | 0.234378″ | 5.95312 |

| #14 | 1/4″ | 0.250″ | 6.35 |

| #16 | 17/64″ | 0.265626″ | 6.74687 |

| #18 | 19/64″ | 0.296875″ | 7.54062 |

| #20 | 5/16″ | 0.3125″ | 7.9375 |

| #24 | 3/8″ | 0.375″ | 9.525 |

Length of Screws / Bolts

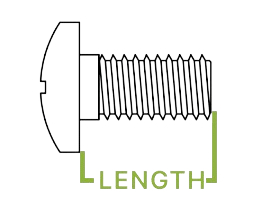

The distance from the head to the tip or blunt end defines the length of screws and bolts. All screw types are either flat on the top or bottom. The following are some tips for how to measure screw/ bolt length.

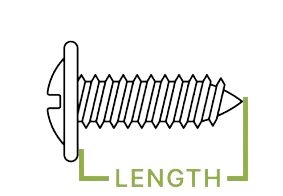

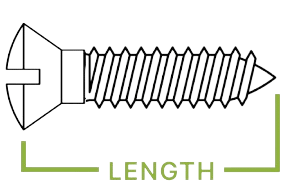

The majority of screws, such as pan head, round head, truss head, and others, have a flat bottom on the head. The measurement for all these types is taken from the bottom of the head to the tip.

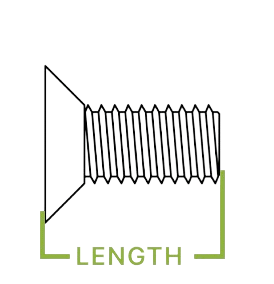

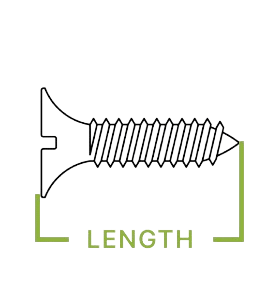

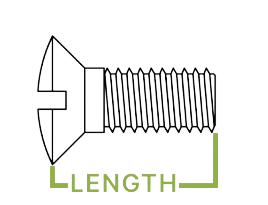

Those that have a flat top, like flat head and countersunk screws are measured from the top of the head to the tip.

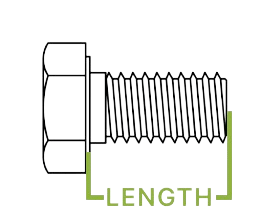

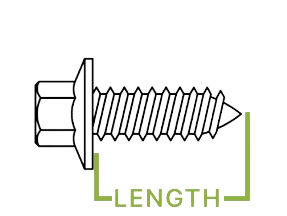

Hex and hex washer head screws and bolts are flat on both the top and bottom, but their length is determined from the bottom of the head.

Hex and hex washer head screws and bolts are flat on both the top and bottom, but their length is determined from the bottom of the head.

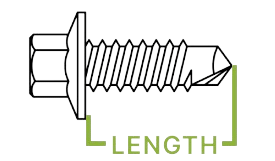

For self-drilling screws, the measurement extends to the very end of the drill point tip.

Thread Pitch of Screws / Bolts

Thread pitch is how far apart each thread is on a screw. You can measure this from the top of the thread (the crest), the bottom (the trough), or anywhere in between.

How to measure thread size? When measuring thread pitch in metric units, it’s done in millimeters. Remember, larger pitches mean the threads are further apart (coarser), and smaller pitches mean they’re closer together (finer). This is important for understanding how strong a screw is and how easy it is to install.

For screws measured in inches, thread pitch is the number of threads in one inch, called threads per inch (TPI). You just count the threads in a one-inch section of the screw. Fewer threads per inch means coarser threads, while more threads per inch means finer threads. Just like in metric, these details affect the screw’s strength and how easy it is to install.

In Imperial units, thread pitches fall into two main categories:

- Unified National Coarse (UNC) – These offer high strength with fewer and deeper threads and are commonly used in heavy mechanical structures. However, its self-locking capability is not as strong as fine-threaded screws.

- Unified National Fine (UNF) – Known for its excellent sealing properties from more threads, fine-threaded screws are frequently used in precision assemblies and are suitable for fine adjustments.

Contact Fivetech

Should you require assistance or struggle to locate the specific screw size you need, consider consulting a reliable specialty fastener manufacturer. Fivetech offers tailored solutions to match your unique requirements in terms of size, material, and strength. We take pride in producing specialty fasteners based on customer-provided blueprints.

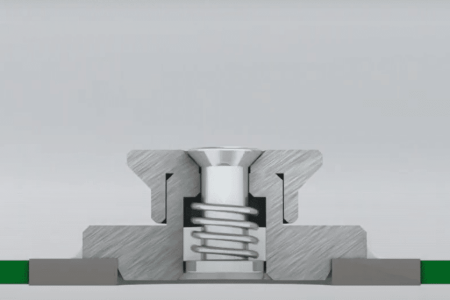

One of our excellent solutions is captive screws. Unlike conventional screws, captive screws can be unscrewed from their corresponding part within the machine’s body. The special feature is that captive screws remain firmly attached to the panel itself, which resolves a common challenge for engineers, losing screws. This ingenious design ensures that you can effortlessly and safely replace the panel once internal maintenance is complete. For more outstanding solutions in Fivetech? Press the button below to contact us!

Seeking the product for your challenging applications?

You Might Also Like

|

|

Mastering PCB Standoffs: A Comprehensive Guide to SMT Solutions |

|

An M.2 Screw Alternative: A Deep Dive into M.2 Board Latches |

A Guide to Folding Handles: Embracing Compactness and Functionality |

➤ Fivetech’s Thumb Screws: Convenient and Reliable

➤ Exploring Riveting Machines: Advantages, Types, and Selection Tips – Fivetech