A riveting machine is a specialized tool designed to join materials using rivets efficiently. This mechanical device inserts and secures rivets, significantly improving manufacturing and construction speed, precision, and consistency. Riveting machines apply force to deform the rivet, creating a permanent, vital connection between materials. They come in various types according to their operating principle.

In this article, we’ll delve into the advantages of riveting machines, explore their different types,and provide a guide for selecting the suitable machine for your needs.

Operation Principle of Riveting Machine

Riveting machines operate on a three-axis principle, controlling movement along X, Y, and Z axes for precise positioning. The process begins by establishing a zero point or base point. Operators input coordinates and heights for each riveting point into the machine’s data entry system. Once programmed, the machine’s servo mechanism guides the workpiece to the first designated point, aligning it beneath the rivet head.

The system calculates the appropriate feed amount for riveting. With all parameters set, the machine executes the riveting process, moving systematically through each programmed point. This automated, coordinate-based system ensures accuracy and consistency in rivet placement across complex workpieces.

Image by https://ideogram.ai/t/explore

Benefits of Riveting

Riveting offers numerous advantages in manufacturing and construction. Here are key benefits that make them an indispensable method in various industries:

- Environmentally friendly: No harmful fumes or gases are produced during the riveting process, unlike welding.

- Superior strength: Riveted joints excel in high-vibration and impact-force applications, offering enhanced reliability.

- Minimal thermal impact: Riveting causes little to no damage to material coatings due to its low thermal effects.

- Easy dismantling: Riveted joints can be removed with less damage than welded joints, ideal for future maintenance.

Benefits of Using Industrial Riveting Machines

An industrial riveting machine can significantly improve productivity and quality. Let’s explore the key advantages that make industrial riveting machines a valuable addition to your equipment arsenal:

- Cost-effective: Rivets are economical, making riveting a budget-friendly joining method.

- Rivet versatility: Riveting machines can handle various rivet types, accommodating different materials and applications.

- Safety: Riveting machines reduce the risk of workplace injuries compared to manual riveting methods.

- Productivity: Riveting machines streamline the riveting process, allowing for faster and more consistent output compared to manual methods.

- Enhanced precision: Machine riveting ensures uniform joint quality, reducing errors associated with manual riveting.

Types of Riveting Machines

Riveting machines come in various types, each designed to meet specific industrial needs and applications. These machines can be categorized based on their power source and operating mechanism. Here’s an overview of the main types of riveting machines:

Pneumatic Riveting Machines

Pneumatic riveting machines are widely used in industries like automotive and aerospace to assemble components securely. By using compressed air to generate the riveting force, these machines offer higher speed and precision. Their low cost and ease of maintenance contribute to their popularity across various manufacturing industries, particularly suitable for medium-sized production lines or environments requiring flexible adjustments.

Automatic Riveting Machine

An automatic riveting machine automates the process of fastening materials using rivets, combining drilling and riveting in a single operation. It feeds rivets into a hopper and positions materials under a ram or punch, which drives the rivet through and forms a secure head on the opposite side.

This is particularly important for applications like server enclosures, which require numerous rivet points. Additionally, the machine can be operated through pre-programmed settings, reducing the likelihood of human error and making them ideal for large-scale, standardized production lines.

Hydraulic Riveting Machines

Hydraulic riveting machines are designed for demanding tasks in industries like construction and shipbuilding, where solid and secure rivets are essential. Unlike pneumatic versions, these machines utilize hydraulic pressure to set rivets, relying on a system that includes a hydraulic pump, throttle valve, and gear pump. This setup enables precise control and allows the riveting head to pause at any point during its operation, making it ideal for heavy-duty applications.

Orbital Riveting Machine

An orbital riveting machine, also known as a radial riveting machine, operates by securing rivets using a rotating orbital motion. Driven by an electric motor, the machine features a rotating shaft and rivet head. When activated, the rivet head applies pressure while rotating, generating radial and axial forces that fasten the rivet securely. This method is ideal for delicate materials, offering efficient, even force distribution and versatility for workpieces of varying shapes and sizes.

Tips of Riveting Process

Understanding how to use a riveting machine is crucial for ensuring precise alignment, proper material positioning, and achieving strong, secure joints, which are essential for maintaining the integrity and quality of the assembly. Here are simple tips and a video for a detailed demonstration.

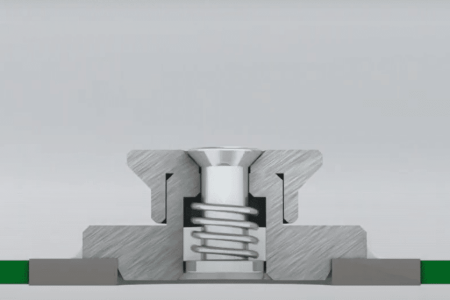

- Position materials: The clinching nut is placed in a die fixture that fits just enough for a nut. The depth of the hole of the above tooling is equal to the outer circle height of the pressure rivet nut; the so-called outer circle height of the pressure rivet nut refers to its T value.

- Aligning with the material: Align the holes of the sheet with the pressure rivet nut and place it on it. The fit between the plate hole and the nut involved here, the specification of the pressure riveting nut has a table of relevant parameters in this link, generally speaking, the plate hole diameter is slightly larger than the C value of the nut.

- Pressing into the riveting machine.

What to Consider When Selecting Riveting Machines

Choosing the right riveting machine is crucial for meeting current and future needs. Manufacturers seek versatile, reliable devices that can handle varying press pressures while being cost-effective. As business demands grow, understanding how to select a machine that adapts to both anticipated and unforeseen requirements ensures long-term performance and customer satisfaction.

- Riveting rate: When selecting a riveting machine, considering the volume of work and the fastener insertion rate is vital. An automated press is more cost-effective for high-volume jobs exceeding 50,000 fasteners, as it operates 5-6 times faster than a manual machine, significantly boosting productivity.

- Machine compatibility: To boost productivity, prioritize machines that allow easy tool changes and accommodate various fastener types and sizes. Ensuring compatibility for “vertical integration” between manual and automatic feed tools across different presses can reduce costs and enhance machine efficiency by minimizing the need for additional tools.

- Safety systems: Prioritize machines with well-integrated safety systems designed from the outset, not as an afterthought. Reliable safety features are crucial for enhancing worker confidence and minimizing accidents. Ensure the safety systems are comprehensive, mainly if the equipment includes electrically conductive tools within the safety circuit.

Image by https://ideogram.ai/t/explore

Another Key Role – Fastener

High-quality fasteners are crucial for riveting machines because they ensure secure and reliable joins between materials. Inferior fasteners may lead to weak or inconsistent rivets, compromising the integrity and durability of the assembled product. Quality fasteners enhance the efficiency of the riveting process, reduce the risk of defects, and ultimately contribute to a more robust and long-lasting final product. Investing in high-grade fasteners minimizes downtime and maintenance, improving overall productivity and reducing long-term costs.

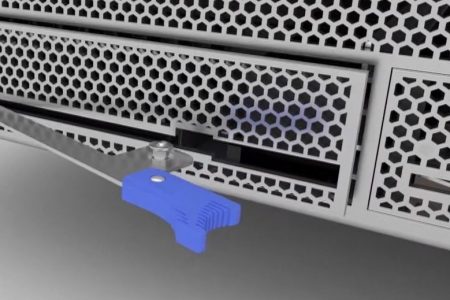

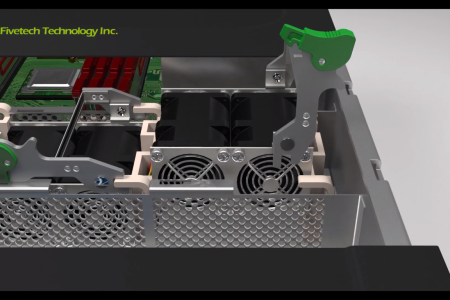

Explore Various Quick Release Fasteners at Fivetech

Quick-release fasteners drastically reduce time and manual labor, considerably boosting efficiency and transforming assembly methods in numerous industries. Fivetech stands out with its extensive range of innovative solutions, from quick-release screws to handle and roller systems, which are all ISO certified and RoHS compliant.

Our commitment to quality and innovation ensures reliable and high-performing solutions for many mechanical needs. We also offer stable, large-scale production and timely delivery services to ensure uninterrupted supply and quick replacement to reduce downtime. Visit Captive Fastener – Fivetech and Quarter Turn Fastener – Fivetech for your needs. If you want special sizes or functions, contact us for our customization services!

Searching for a suitable solution for your design!

Relative Read

➤ Ultimate Guide to Captive Screws: Types & Applications

➤ Fivetech Quick Release Fastener | All Solutions

➤ Discover M.2 Board Latches: The Perfect M.2 Screw Alternative

➤ Mastering PCB Standoffs: A Comprehensive Guide to SMT Solutions

➤ A Guide to Folding Handles: Embracing Compactness and Functionality

➤ Understanding Server Hardware & Its Main Components – Fivetech

➤ How to Measure Screws, Bolts, and Threads Sizes – Fivetech