1. Server Cooling: Overview

Server cooling is the technology used to maintain electronic components within a server room or data center at optimal temperatures. It is crucial for ensuring reliable and efficient operations, especially with the ever-increasing processing demands of modern computers and communication infrastructure.

1.1. Why Does Server Cooling Matter?

Excessive heat can cause server hardware to fail, leading to data loss, system downtime, and costly repairs. With server cooling, the components can remain at an estimated temperature range of 68-72°F, which makes them less prone to errors and crashes. Not only will this prevent overheating and help the servers operate at their peak performance, but it can also minimize the risk of safety hazards like power outages or fire outbreaks.

1.2. Professional Server Cooling Systems vs. Conventional AC

So, why can’t data centers rely on air conditioning to cool down servers? While a traditional air conditioner can provide some cooling effects, it’s often insufficient for server rooms due to several factors, including:

- Temperature Precision: Server rooms tend to fluctuate in temperature due to the high heat density and processing demands that vary throughout the working period. As such, the room has to be controlled to a precise temperature within a narrow range. This can be difficult to achieve with a standard AC unit.

- Humidity Control Requirement: High humidity can create condensation issues within server cabinets, which usually can’t be solved with a standard air conditioner. Many professional systems include features to control humidity levels, which can help prevent condensation and ensure optimal server performance.

- Extended Operating Periods: Data centers typically operate 24/7, thus requiring constant cooling. Keeping conventional AC systems on for extended periods can easily lead to breakdowns. On the other hand, server cooling systems are designed for reliability and minimal downtime over long periods of operation.

- Scalability: As the data center expands and the number of servers increases, the cooling requirements may exceed the capacity of an existing air conditioner. While it may be difficult and expensive to upgrade the building’s system, professional server cooling systems can be modular and scalable, allowing for easy expansion.

2. Types of Server Cooling System

In this section, we will explore the key types of systems and explain how they cool a server room. By understanding the features, advantages, and disadvantages of each system, you can select the most appropriate cooling solution for your specific server environment.

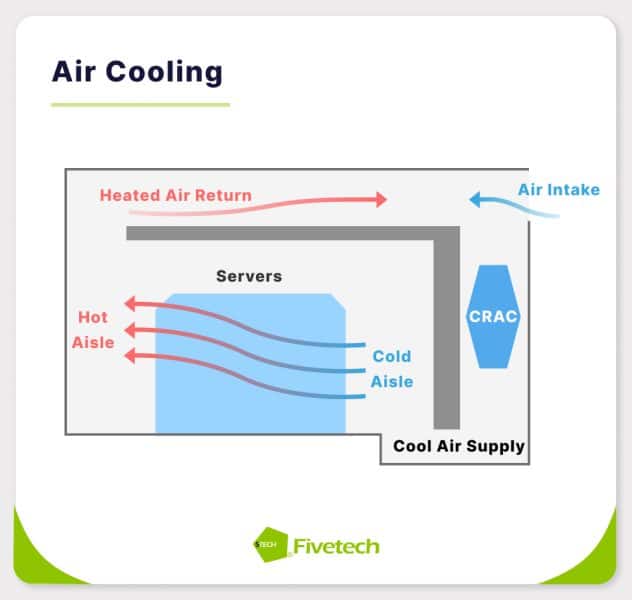

2.1. Air Cooling

Air cooling is the most traditional method of server cooling. It involves circulating air around server components to dissipate heat. The two primary methods of air cooling include:

- Fan-Based Cooling: This approach utilizes fans to draw in cool air and expel hot air from server cabinets. Fans can be installed within the server itself or at the rack level. Server-level cooling is suitable for smaller data centers, while rack-level cooling can be more efficient for higher-density environments.

- Air Duct Cooling: This method involves using air ducts to channel cool air directly to server components and efficiently remove hot air. These air ducts can usually be customized to optimize airflow within server cabinets and improve cooling efficiency.

Air cooling systems are relatively simple to implement and maintain, which is why they are more cost-effective compared to liquid cooling, especially for smaller data centers. They can also be easily scaled, making them a versatile option.

Despite that, air cooling may not be as efficient as liquid cooling for extremely high-density server environments. It can also be less effective in hot climates or environments with limited airflow. Moreover, the fans can generate noise, which may be a concern in certain locations.

Due to these features, air cooling is commonly used in smaller server rooms with lower server densities and less stringent cooling requirements. It’s also a good choice for general-purpose servers in offices or small businesses, as they have moderate heat generation and don’t require extreme cooling capabilities.

2.2. Liquid Cooling

Liquid cooling systems typically utilize sealed tubes, called cooling loops, filled with a liquid coolant. Heat is transferred from the server components to the coolant through cold plates, and then the coolant is circulated through an exchanger to dissipate the heat. There are two main types of liquid cooling, which dissipate heat with different methods:

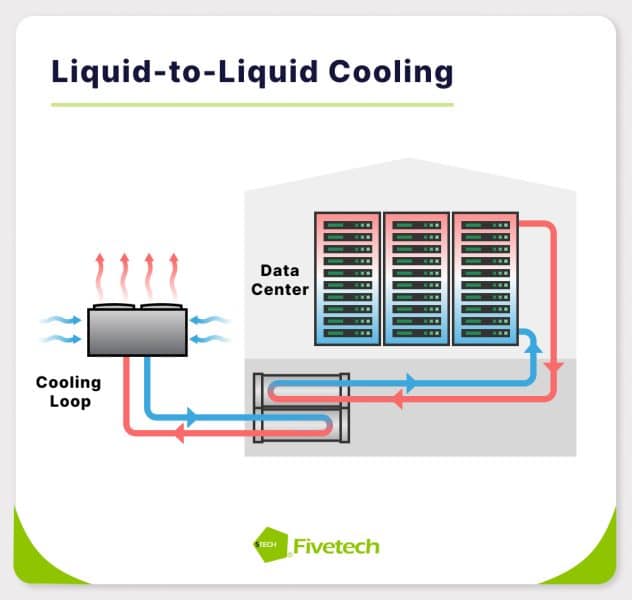

- Liquid-to-Liquid Cooling: This method involves transferring heat from the initial coolant to a larger liquid-based cooling loop within the data center, where the secondary liquid coolant will absorb the heat from various sources, including liquid-cooled servers. This allows for even more efficient heat removal and can support higher server densities, but may not be suitable for confined spaces due to the requirement of a large central cooling loop.

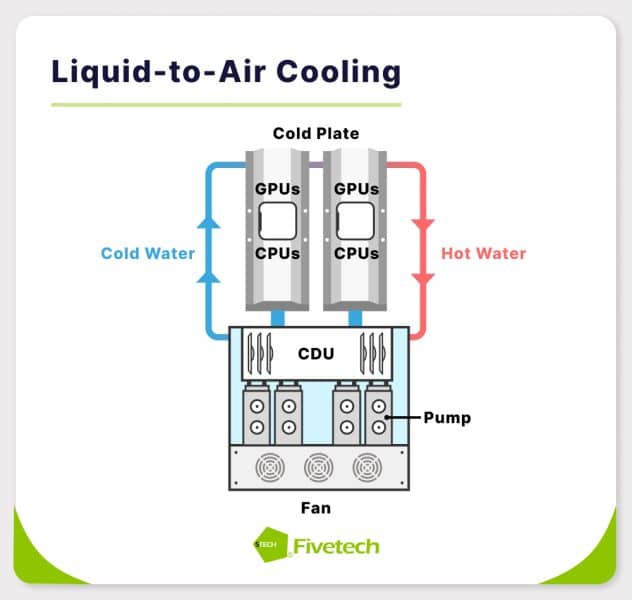

2. Liquid-to-Air Cooling: This hybrid system combines elements of air and liquid cooling. Liquid-cooled servers are installed in standard racks, and the cooling loops are connected to heat exchangers. The heat is then transferred from the coolant to the surrounding air, similar to traditional air cooling. This approach is suitable for data centers that want to incorporate liquid cooling without completely overhauling their existing infrastructure.

While air cooling has relatively lower hardware costs, liquid cooling systems are significantly more efficient than air cooling at transferring heat, especially in high-density environments, with heat dissipation capabilities that are 3.5 times higher. By boosting efficiency and enabling denser server packing, liquid cooling allows for more computing power within a smaller space and lower energy consumption. Hence, it is predicted that the market preference will gradually shift towards liquid cooling as high-performance chip technology continues to advance.

However, liquid cooling systems have a potential risk of leakage, which may further cause severe damage to the server and result in data loss. Therefore, it is important to deploy efficient sealing strategies and detection systems when using liquid cooling.

Still, liquid cooling offers greater flexibility compared to immersion cooling, as they are easier to integrate into existing data center infrastructures, making them a more economical and efficient solution. As such, liquid cooling is particularly ideal for applications that require high performance and efficiency, such as high-performance computing (HPC) clusters, large-scale data centers, and edge computing environments.

2.3. Immersion Cooling

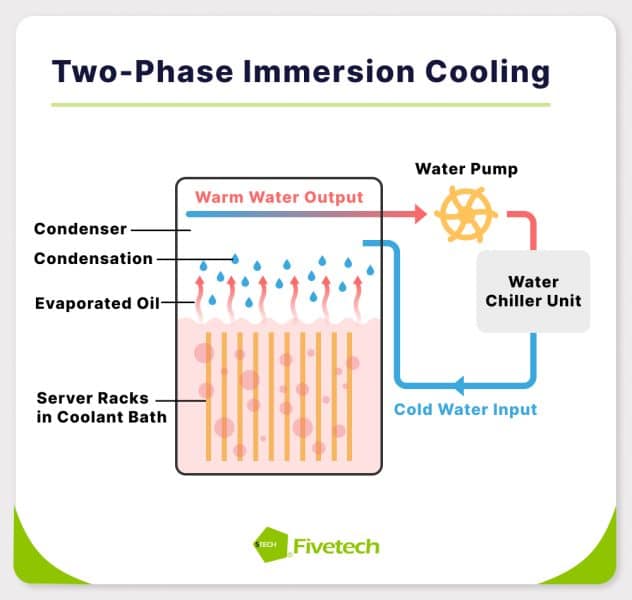

Immersion cooling is a more advanced form of liquid cooling. It involves submerging servers and other IT equipment directly in a dielectric (electrically non-conducting) liquid to remove heat. This liquid is typically a form of synthetic hydrocarbon that possesses excellent thermal conductivity, low viscosity, and remains in a liquid state even under extreme temperatures.

This approach eliminates the need for fans or cold plates, as the dielectric liquid directly absorbs heat from the server components, providing unparalleled cooling performance. Immersion cooling can also be further categorized as:

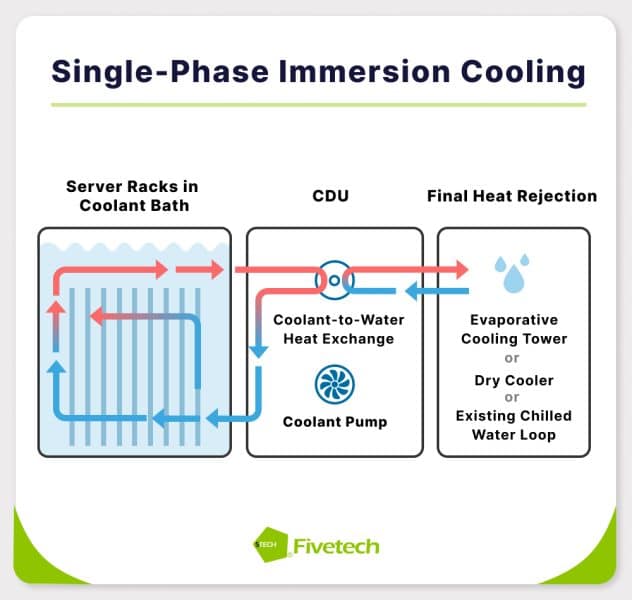

- Single-Phase Immersion Cooling: In this method, the dielectric liquid remains in a single phase throughout the cooling process. Heat is transferred directly from the server components to the liquid, while the coolant distribution unit (CDU) circulates the heated liquid throughout the tank to ensure even heat distribution. Then, the heated liquid is pumped to a heat exchanger, where it transfers its thermal energy to a secondary coolant. Subsequently, the cooled liquid is returned to the tank, completing the cycle.

By eliminating the need for bulky components such as fans and heat sinks, immersion cooling can promote space efficiency and help users increase the density of processing hardware. This allows servers to expand their capabilities and operate at maximum performance, maintaining reliability, even in smaller data centers.

Moreover, as immersion cooling relies on heat circulation through passive, natural processes like condensation and vaporization, it reduces unnecessary energy consumption and offers better power usage effectiveness (PUE), cutting down electricity and water management costs.

Nevertheless, immersion cooling requires specialized equipment, such as advanced monitoring and control systems for tracking fluid levels, temperature, and other parameters to ensure optimal performance, so it can take up more space and may need expertise to manage. Traditional data centers may even have to undergo costly and time-consuming large-scale renovations to accommodate these new infrastructures.

Additionally, the choice of non-conductive coolants is critical to prevent electrical damage in immersive cooling systems. However, these specialized coolants are costly and need regular replacement due to degradation from long-term operation, adding to maintenance expenses. Handling the coolant also presents challenges, as disposal processes must adhere to strict environmental regulations.

A key concern with immersion cooling is the risk of leaks. Despite the use of non-conductive fluids, any leakage can still damage servers and equipment, necessitating robust leak-proof design and frequent inspections to ensure safety. Maintenance can be further complicated, as servers need to be periodically removed for inspection and drying, which, if done improperly, may affect circuit stability and degrade the quality of the coolant.

While these challenges may be complex and not cost-efficient for smaller operations, it can be substantial for data centers with demanding requirements, including supercomputing centers, high-performance research facilities, and other specialized data centers that need to push the limits of server performance.

2.4. Supplementary Server Cooling Equipment

Thermal Sensor

Thermal sensors are devices used to continuously monitor the temperature of critical server components. They can be integrated into server motherboards or attached as standalone devices, providing accurate readings of the attached component’s temperature.

The features of thermal sensors are particularly helpful when used in conjunction with other cooling technologies, such as smart controls. Although this might add a layer of complexity to a cooling system, they are essential for maintaining the temperature of key server components like CPUs, GPUs, and power supplies.

Smart Control

Smart control systems are cutting-edge technologies that leverage sensors and algorithms to optimize server cooling performance. By utilizing sensors to gather data on temperature, workload, and other relevant parameters, smart control systems can accurately assess the cooling needs of individual servers or groups of servers. This real-time information is then used to adjust cooling settings, such as fan speeds or coolant flow rates.

These systems provide automated control and management of cooling systems, freeing up IT staff to focus on other tasks. Smart controls can also detect early signs of overheating, allowing for timely intervention to prevent issues before they become serious safety hazards.

Even though the initial investment for additional hardware and software is more costly, smart controls are ideal for applications that require complex cooling requirements, which are often difficult to monitor and manage manually.

Server Cabinet Cooling

While the primary function of the server cabinets is as a physical enclosure that protects the servers and other components, they also play a crucial role in server cooling by facilitating airflow and preventing heat buildup. They are designed with ventilation openings to allow cool air to enter and hot air to exit, ensuring that components remain at optimal operating temperatures.

When choosing a server cabinet, it is important to make sure it is large enough to accommodate your server equipment while allowing for adequate airflow, as the server equipment should only take up 75% to 85% of the cabinet space. It is also best if it has a perforated door or an open design for increased ventilation.

Furthermore, during installation, the server equipment should be at least 4cm away from the front and back of the cabinet while keeping a space of at least 1U between each row to maintain ventilation. Cable management is also important to prevent heat buildup, so avoid cluttering them. Plus, all unused cabinet space should be sealed with blank panels to prevent hot and cold air from mixing, which could cause temperature fluctuations for the server equipment.

On top of that, data centers also actively circulate air within cabinets by installing fans or air conditioners. With this, the cold air from the room will be drawn into the cabinet through the front door and flow over the servers inside to transfer heat, before being blown out towards the heat exchanger at the cabinet’s rear door. The heat is then directly transferred away from the cabinet to the external cooling systems by the coolants flowing through the rear door.

By selecting a well-designed server cabinet and implementing proper cooling practices, you can significantly improve the overall efficiency and reliability of the data center. As a reference, this video by Delta America demonstrates the ideal setup to facilitate cooling for server cabinets:

3. Components of Common Server Cooling Systems

Now that you understand how different server cooling systems work, you will also realize how they require various interworking components to remove heat effectively. We will now provide a brief breakdown of the key components in air cooling and liquid cooling, the most common types of server cooling systems, helping you gain a deeper insight into their design.

3.1. Air Cooling

As a system that relies on the circulation of air to dissipate heat, air cooling mainly consists of:

- Fans: Installed within individual servers or at the rack level, these fans are used to draw in cool air and expel hot air from server cabinets.

- Heat Sinks: Metal structures that absorb heat from server components and dissipate it into the surrounding air. They are typically attached directly to critical components like CPUs and GPUs.

- Computer Room Air Conditioning (CRAC) Units: CRAC units are large high-efficiency air conditioning systems designed specifically for data centers. They provide chilled air to cool the entire server room.

- Ducts: Ducts installed in and out of the server cabinets act as conduits, channeling air from cooling sources, such as fans or CRAC units, to server components and back, facilitating efficient airflow and heat distribution.

3.2. Liquid Cooling

Due to the requirement of liquid substances for heat dissipation, liquid cooling systems are more complex than air cooling. Its key components include:

- Coolant (Cooling Fluid): The liquid used to transfer heat. Common coolants include water, glycol mixtures, and synthetic oils.

- Cold Plates: Metal plates that come into direct contact with server components, transferring heat to the coolant.

- Pumps: Pumps circulate the coolant throughout the liquid cooling system to ensure efficient heat transfer.

- Manifolds: These piping systems ensure the even distribution of coolant to individual cold plates in servers or server racks. It also collects the heated coolant and returns it to the cooling system for recirculation.

- Heat Exchangers: Devices facilitating heat transfer between two fluids in liquid-to-liquid cooling systems.

- Radiators: Radiators are used to dissipate heat from the coolant into the surrounding environment, especially in liquid-to-air cooling systems.

- Cooling Fluid Distribution Units (CDUs): Centralized monitoring units that manage the flow and distribution of coolant throughout the liquid cooling system. They are also used to adjust the system’s pressure, temperature, flow rate, and other relevant parameters to maintain optimal performance.

3.3. Role of Fasteners in Cooling Systems

Fasteners are essential components in server cooling systems, providing the structural integrity necessary for proper functionality, as they ensure cooling components remain firmly in place during operation. This minimizes the risk of component loosening, failures, and server downtime.

Fasteners also offer secure and accurate positioning, thus optimizing heat transfer to maintain overall cooling efficiency. Those offering unique features such as quick-release and smart folding mechanisms can even make maintenance tasks easier and more efficient.

The types of fasteners ideal for cooling system applications include:

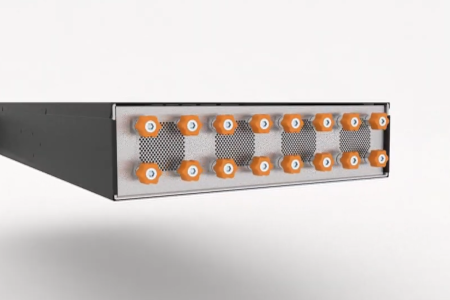

1. Quarter Turn Lock

The quarter turn locks provide a strong connection when securing cooling fans or other components to the motherboard. These fasteners also feature a quarter-turn mechanism, which can be operated without tools, allowing for quick, easy installation and removal to boost the maintenance efficiency of cooling systems. Its built-in spring also provides shock absorption to help protect the components and prevent accidental disconnection.

Another model of this fastener is the Auto Quarter Lock which features a high-stability, high-strength metal stopper that ensures long-term reliability and durability.

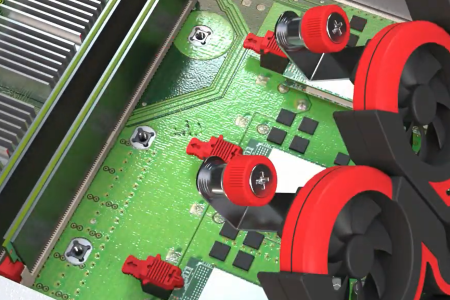

2. Adjustable Fastener

It is important to avoid overtightening fasteners when assembling cooling components within servers, as uneven pressure between the cooling plate and CPU/GPU could affect the heat transfer efficiency of the thermal paste, potentially damaging the processor or other sensitive components. For air cooling, uneven force can make the fans more susceptible to wear and tear or even cause failure. Yet, if the screws are too loose, the fan may vibrate and become loose.

In this case, most engineers would opt for fasteners with automatic pressure adjustment features, such as Fivetech’s plunger, spring lock, ball lock, etc, to ensure optimal heat transfer and structural integrity.

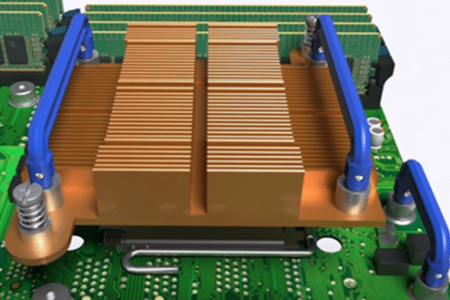

3. Smart Folding Handle

Cold plates are often heavy, posing a significant risk of being dropped and causing accidental damage to their delicate components. By attaching smart folding handles, cold plates can be operated safely and conveniently. Its 90-degree folding design also saves space. Moreover, manufacturers like Fivetech often incorporate heat-resistant plastic that can withstand high temperatures for their smart folding handles, leveraging its lightweight and insulating properties to prevent scalding or other operational hazards.

4. Infinity Screw

While screwdrivers are usually used to tighten screws for large heatsinks, there is a risk of over-tightening due to the inability to accurately control the torque, which could potentially damage the components. Additionally, conventional long screws are made in a single-piece design, making them prone to bending over time.

On the other hand, infinity screws with segmented design are less likely to deform during use, making them reliable for cooling system applications. They can even be extended or shortened according to the user’s needs, allowing for quick replacement and repairs of multiple modules.

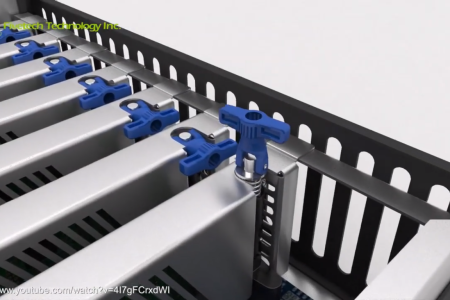

5. Rotate Ejector

Relying on a simple lever operation, rotate ejectors incorporate a push-back/positioning mechanism that enables quick and easy disconnection or blind mating of QD (Quick Disconnects) connectors in liquid cooling systems. This feature ensures precise alignment and prevents accidental damage to the water cooling connectors.

6. Spacer

Spacers support and elevate PCBs to maintain optimal space between components, allowing for efficient heat dissipation. Not only can this reduce the risk of damage to surrounding components, but it can also free up more space by enabling multi-tiered assembly within the server rack, allowing for better functionality in the overall system.

7. Roller

As servers become heavier with the addition of advanced liquid cooling systems, rollers can help reduce friction and enable smoother movement of the server chassis. They can also help operators effortlessly slide the cooling equipment within the rack to significantly improve maintenance efficiency while reducing the risk of accidental damage to equipment and injuries to personnel.

Reputable manufacturers like Fivetech offers a wide variety of high-quality roller series solutions that are lightweight, compact, and easy to push and pull. The modular design of these components also enable easy installation on the sides and bottom of the chassis. Their sizes can even be customized to meet specific requirements.

4. How to Choose Server Cooling Solutions

Selecting the right cooling solution for your server room ensures optimal performance, reliability, and energy efficiency in the data center. It requires careful consideration of several key factors, including:

- Cost: Establish a budget and prioritize factors based on your specific needs. For example, while liquid and immersion cooling offer superior heat dissipation, they often require specialized infrastructure such as dedicated liquid supply and cooling loops. This may be more cost-effective for larger server environments, but may be expensive and unnecessary for low-density servers. Take your time to compare different cooling systems and identify cost-saving opportunities, ensuring you make an informed decision to get the best value for your money.

- Data Center Layout: Your data center’s specific layout and design will influence the most suitable cooling solution. For instance, air cooling relies on efficient airflow within the environment, so it may not be ideal for tightly packed servers, which may require liquid cooling or immersion cooling instead.

- Thermal Design Power (TDP): Selecting a suitable cooling system based on the TDP is essential for optimal performance. Measured in watts (W) or kilowatts (kW), TDP refers to the maximum amount of heat a CPU or GPU can generate when operating at its highest load. By ensuring that the cooling system’s heat dissipation capacity meets the TDP, users can maintain optimal IC speeds and prevent the system from overheating.

- Scalability: Choose a scalable cooling system to accommodate future growth and avoid costly remodeling. Modular cooling systems with variable speed operation and simplified spare parts offer flexibility in cooling capacity. This allows for incremental scaling as your cooling demands increase, maximizing the lifespan of your infrastructure investments.

- Maintenance and Serviceability: Consider the long-term maintenance requirements and costs associated with the cooling solution. As an example, systems with self-diagnostic capabilities and reduced stress on critical components can minimize maintenance issues and downtime. You can even choose cooling technologies with easier maintenance access, ideally, those incorporated with quick-release fasteners to eliminate the need for tools, promoting operational convenience and efficiency.

5. Revolutionize Your Server Cooling Solutions with Fivetech’s Advanced Fasteners

Fivetech offers a range of specialized fasteners ideal for applications in server cooling systems, from quarter turn locks to smart folding handles, rotate ejectors, and even customized solutions. Verified by ISO and RoHS certifications, these fasteners are designed to enhance the durability, reliability, and ease of maintenance of cooling components, thus contributing to the overall performance of data centers.

Moreover, Fivetech prioritizes compact and tool-less solutions to align with the trend of miniaturization in server hardware and cooling systems. So, by choosing Fivetech, you gain access to high-quality components that not only enhance performance but also optimize space within your data center. Explore Fivetech’s innovative server cooling solutions today to elevate your server operations!

Explore Fivetech Server Cooling Solutions